Hi Jay,

Machine looks great, and very clean DRO install, nice. A few things to consider checking the cutting alignment, you may need a precision level to check for any bed twist along the ways. I have some precision ground test bars and I look at the +/- TIR from 0 at different points along the bar. If the swing in the +/- value is skewed in one direction as you get further from the chuck, then you may need to align the headstock. Most of us have had to do this, it takes the slightest change in the alignment bolts. I would also do a test cut with the 4J chuck to see how it compares.

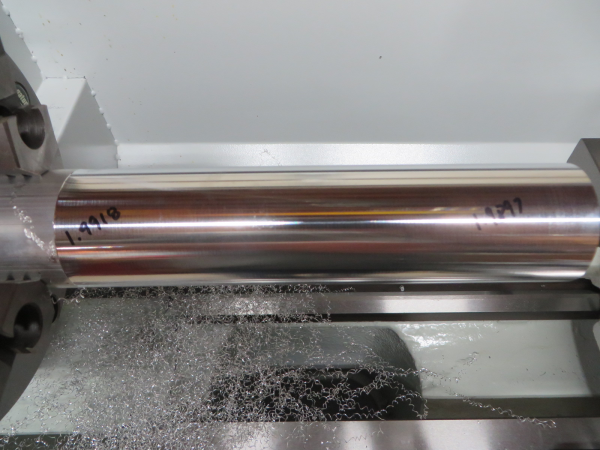

Overall, it appears to be a very fine machine, and that is close to a mirror finish cut on the test cut. Hopefully you have more room for a larger motor in the back if you go the VFD route in the future, Impressive, if I didn't already have a lathe, this is the one I would get today.