- Joined

- Jun 12, 2014

- Messages

- 5,128

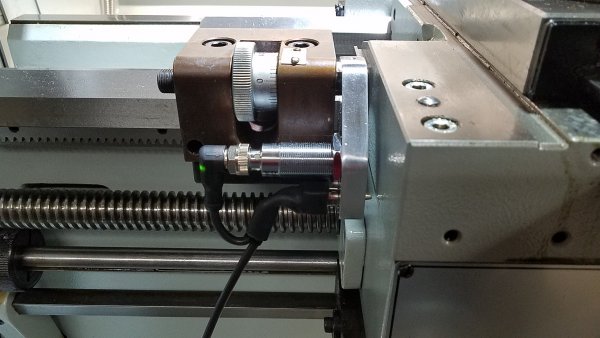

The proximity sensor has an override button which allows you to reverse the carriage once the sensor is triggered. The micro limit safety switch will engage at about 2 mm should you press the P bypass switch and the carriage goes in the wrong direction, i.e you make a mistake and it cannot be bypassed. You physically must disengage the feed and backup the carriage.

If the proximity sensor is unplugged the system will not work, a jumper wire is needed to make the connection of the proximity sensor. You can also make up a cable plug with the bypass from the brown wire connected to the white wire.

As Jbolt mentioned it is also there as a redundant safety stop should the P sensor fail, although they have a lifetime warranty and if they did fail the system it would shut down the system. The other issue has been high feed rates such as threading below 20 TPI at over 400 RPM, the P sensor will trigger but the carriage travel in 1 second exceeds the sensor trigger range of 8 mm. I am experimenting with a 12 mm sense range proximity sensor, it works well but the accuracy is a bit less because of the lower refresh rate of the sensor. Repeat accuracy has been within 0.004" as opposed to 0.0004" when threading at 450 RPM with a M16-2.0 which is around a 13 TPI. High feeds like this were not possible with a 8 mm sense range.

Safety micro limit switch is below the P sensor. When the micro limit switch is fully depressed the switch plunger must be flush with the stop face otherwise the switch will be damaged.

If the proximity sensor is unplugged the system will not work, a jumper wire is needed to make the connection of the proximity sensor. You can also make up a cable plug with the bypass from the brown wire connected to the white wire.

As Jbolt mentioned it is also there as a redundant safety stop should the P sensor fail, although they have a lifetime warranty and if they did fail the system it would shut down the system. The other issue has been high feed rates such as threading below 20 TPI at over 400 RPM, the P sensor will trigger but the carriage travel in 1 second exceeds the sensor trigger range of 8 mm. I am experimenting with a 12 mm sense range proximity sensor, it works well but the accuracy is a bit less because of the lower refresh rate of the sensor. Repeat accuracy has been within 0.004" as opposed to 0.0004" when threading at 450 RPM with a M16-2.0 which is around a 13 TPI. High feeds like this were not possible with a 8 mm sense range.

Safety micro limit switch is below the P sensor. When the micro limit switch is fully depressed the switch plunger must be flush with the stop face otherwise the switch will be damaged.