- Joined

- Aug 2, 2020

- Messages

- 691

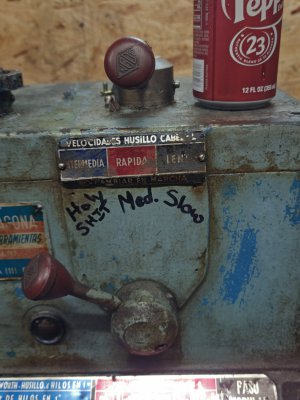

It looks like a nice machine but at the moment it is still a pig in a poke.

It appears to have a good single phase 110/220 reversible motor on it now. Just wire it for 110V and plug/unplug it so you can evaluate the condition of the rest of the lathe. Or put a simple 20 amp single pole switch on it. You don't need it to reverse or be 3 phase or any of those things now - and a lot of folks never do need that stuff.

Why spend a bunch of dough on it before you know what you bought?

It appears to have a good single phase 110/220 reversible motor on it now. Just wire it for 110V and plug/unplug it so you can evaluate the condition of the rest of the lathe. Or put a simple 20 amp single pole switch on it. You don't need it to reverse or be 3 phase or any of those things now - and a lot of folks never do need that stuff.

Why spend a bunch of dough on it before you know what you bought?