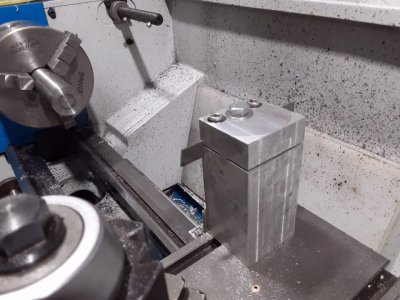

Appreciate the support. I am usually a closed-mouth guy. Opinions are like you-know-what, and typically I like to keep mine covered. A while ago, I asked a question about parting. One of the nice fellows here answered me privately with some drawings and suggestions. Those are posted now in the first post. Took some measurements on my machine, which is a 1030PM, and then adapted the concept.

Parting on the 1030 was always an iffy affair, with the tool holder tip held to a different height with every in or out adjustment, making height and squareness difficult to achieve, with the quick change post on top of the compound and that on top of the cross-slide. With chips piling up in the slot and the invariable dig-in and stall of the spindle. Every time. Took to dismounting the work and using a bandsaw. And then mounting in the mill's radius jaws and squaring off the end.

After a few weeks of spare time in development, had it done. Gave it a try on a chunk of 1.5 1018 round bar (hot roll). Blade tip was dull. Forgot to add lubricant at first. Did it matter? No. I sent my mentor thanks and a couple of photos. He suggested I post on here. Did that, but offered some unwarranted opinions also. Sorry for that. Sorry also for the comment about arrogance. Came back on to delete that, but it's quoted already.

Can't recover the text in that post as it is gone. Here are the photos.