Yeah, but this method takes none of them out. The cutting forces with this contraption is UP, away from the ways - and the apron isn't tightly held down against up-lift, so rigidity isn't what this is giving you.

Also, this design is likely to give you fatigue cracks at the flexure point over time, faster for aluminum, slower for steel.

^^^ These statements.

Ordinarily, I would have let it go until the OP posted this:

I yield to a superior opinion. I should not post on a forum where I know so little.

Clearly, he is intimidated by you and I admit that I do not like that.

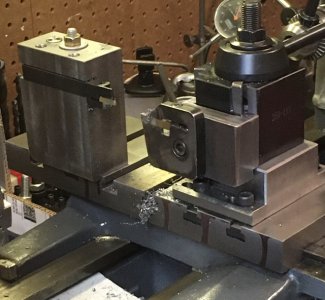

I am the original designer of this tool and yes, it is a tool and not a contraption. It has taken

thousands of chatter-free cuts in just about all machineable materials at 1-3 times normal turning speeds without a hint of chatter. It is extremely rigid and extremely accurate using very thin HSS parting tools that most hobby guys can easily afford. And it will part materials as thin as 0.010" thick and in diameters as large as the chuck will hold. I know it will do all of this because I have done all of this, personally and repeatedly. So, let's be clear. It is a highly effective tool.

I agree that the initial cutting forces at the TIP of the tool are up; that is self-evident. However, these forces are transferred to the body of the tool and into the body of the lathe via the bolt(s) that holds the body of the tool to the cross slide. That bolt acts as a fulcrum and the upward forces are transferred downward to the rear of the tool body to the cross slide, then into the saddle, then onto the ways. All slack or gaps in these structures are taken up and the result is an extremely rigid affair. This allows a light lathe to handle cuts that it normally cannot handle and it does so with no effort. I have studied this in more detail than it deserves in order to work out how these forces are transferred. If you have evidence to the contrary, please do share it.

To be clear, a parting tool used from the front increases these clearances in the bed and it is this arrangement that is less rigid, not the other way around. I've looked hard at this one, too.

As for cracking, maybe. My tool is well over 25 years old and while it is made of aluminum, it has shown zero signs of stress or cracking whatsoever but I admit it is early yet. Maybe in another 25 years it will show some sign but in the meantime I think it will just keep making trouble-free parting cuts for me and others who use this design. There are hundreds of us who do and I have yet to see a single negative report on this tool. I have seen negative comments on the design from those who have never used one, though.

So,

@Pescadora, while your tool is new, it clearly works well for you and I suspect that it will continue to do so for quite some time. It doesn't matter why it works; just that it does.

All of us are free to give an opinion or share our triumphs and I hope that you continue to feel comfortable and welcome here.