- Joined

- Feb 17, 2013

- Messages

- 4,409

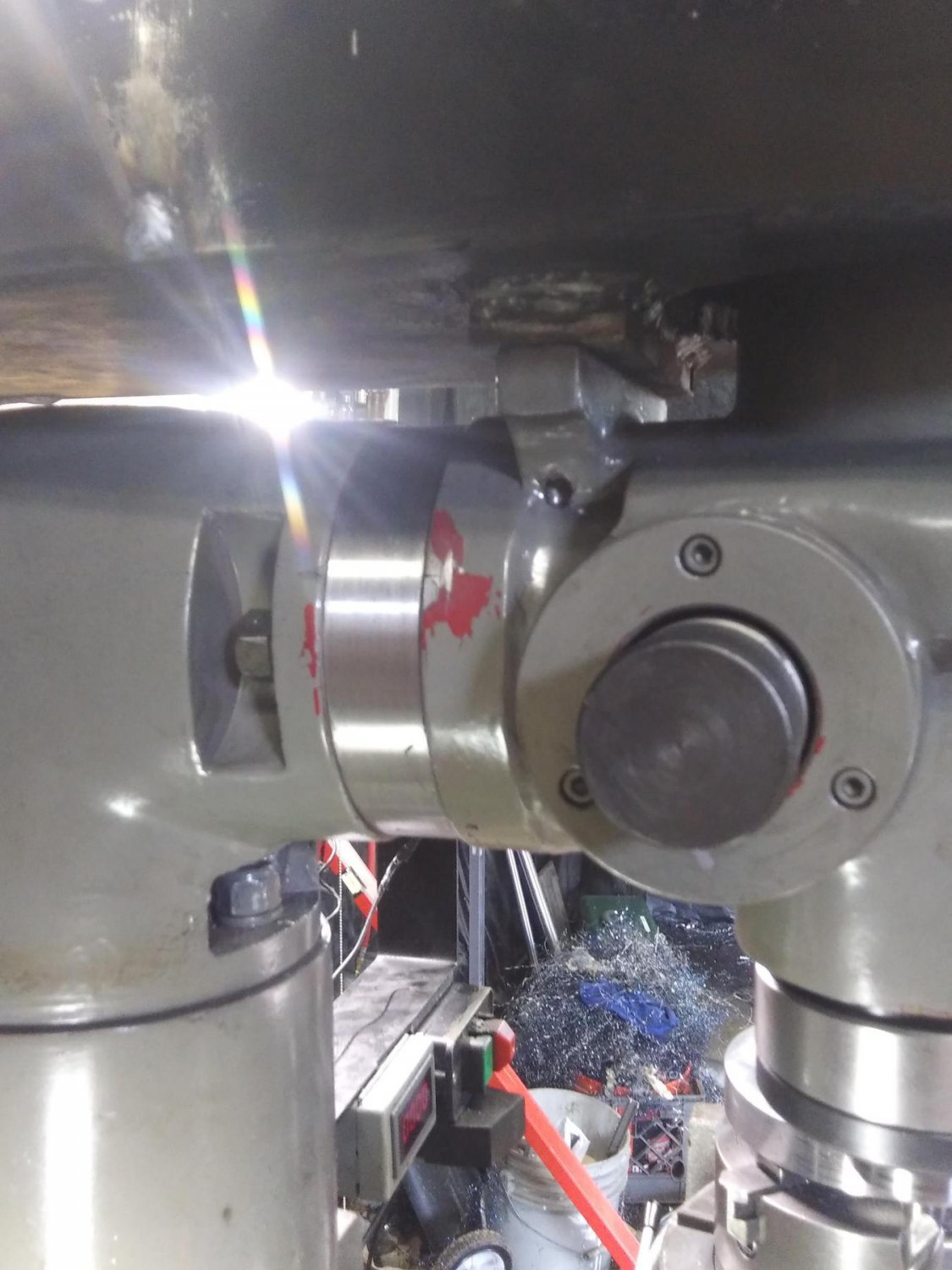

Your mill shoiuld look very nice in grey. Here are a couple of photos from another buyer (found on the HF product page) ... https://www.harborfreight.com/vertical-milling-machine-40939.html:

Late note ... The red color showing through in the first photo makes it look like he simply painted over the original finish.

Late note ... The red color showing through in the first photo makes it look like he simply painted over the original finish.

Last edited: