-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The South Bend heavy 9 Rebuild

- Thread starter Rick_B

- Start date

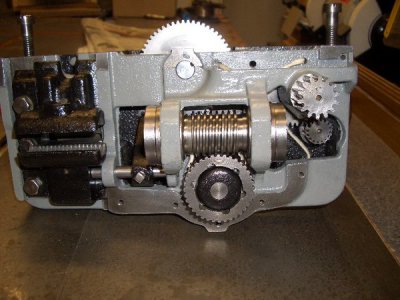

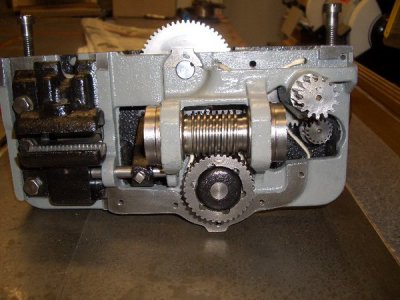

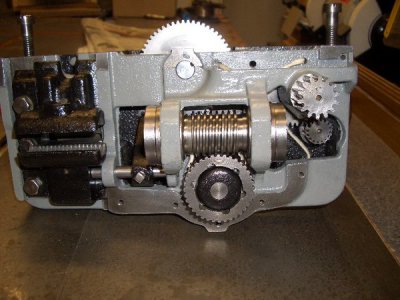

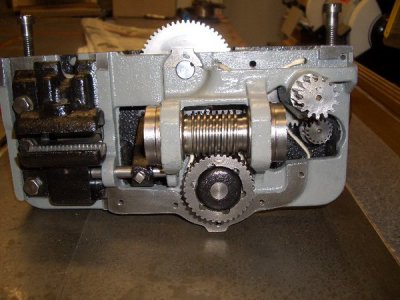

Thought I'd give a brief progress report. I've completed the apron re-assembly - less the chip guard and oilers. I'm waitng for the new worm key to arrive before I complete those pieces.

I also got the pedestal base and tail stock leg levelers installed and have assemble the bed to the pedestal and TS leg along with the chip pan. I got that pretty much leveled at this point. The electrical is also completed and the motor is running as expected through the rotary switch.

Now on to the saddle and cross slide/compound.

I also got the pedestal base and tail stock leg levelers installed and have assemble the bed to the pedestal and TS leg along with the chip pan. I got that pretty much leveled at this point. The electrical is also completed and the motor is running as expected through the rotary switch.

Now on to the saddle and cross slide/compound.

- Joined

- Apr 6, 2011

- Messages

- 2,082

Looks great Rick. Makes me (almost) want to pull mine apart and fix it up nice. :thumbzup:

-Ron

-Ron

Thanks Ron- there's a method to my madness. I started knowing nothing about how a lathe works. I nkow have an iimate understanding of what is going on inside the apron when a control lever or half nut lever is changed.

Rick

Rick

- Joined

- Apr 6, 2011

- Messages

- 2,082

Thanks Ron- there's a method to my madness. I started knowing nothing about how a lathe works. I nkow have an iimate understanding of what is going on inside the apron when a control lever or half nut lever is changed.

Rick

That's the great part of a rebuild. I am having a similar learning experience with my Queen City shaper as I try and bring it back to life. My SB? For the moment I'll "learn vicariously" by watching others do rebuilds. :biggrin:

-Ron

After a lot of help from a number of members here and on other forums (Ronnie and Ted providing a number of needed parts, Iwannanew10k rebuiling the crossfeed screw and compound screw dial and jayhawkman making a new CF nut) Ihave finally gotten the QCGB, apron, saddle, crossfeed and compound back together and reassembled to the lathe.

Now onto the headstock. The lathe came to me without capillary wicks and when disassembling I didn't take a many pictures so I'm looking for some verification on a few things.

in the picture below you will see there is a hole in the headstock casting for what I believe is the capillary wick (one installed) and two smaller holes on each side of it. I believe the smaller holes are vent/oil return holes and don't take any wicks and I think the capillary wick is installed properly. Any disagreement about this?

The second picture is with the spindle installed - does everything look right with this?

Thanks

Rick

Now onto the headstock. The lathe came to me without capillary wicks and when disassembling I didn't take a many pictures so I'm looking for some verification on a few things.

in the picture below you will see there is a hole in the headstock casting for what I believe is the capillary wick (one installed) and two smaller holes on each side of it. I believe the smaller holes are vent/oil return holes and don't take any wicks and I think the capillary wick is installed properly. Any disagreement about this?

The second picture is with the spindle installed - does everything look right with this?

Thanks

Rick

Lubrication Question

i've got the head stock and drive gears reassemble and started oiling it up. Steve's manual recommends teflon grease for the spindle cone pulley and back gear shaft. The SB bulletin "Oiling the Lathe" suggests a few drops of oil in both of theses areas. What-s the best approach? If grease - how much

Thanks

Rick

i've got the head stock and drive gears reassemble and started oiling it up. Steve's manual recommends teflon grease for the spindle cone pulley and back gear shaft. The SB bulletin "Oiling the Lathe" suggests a few drops of oil in both of theses areas. What-s the best approach? If grease - how much

Thanks

Rick

- Joined

- Mar 10, 2012

- Messages

- 1,368

Re: Lubrication Question

I'm in the process of reconditioning my 57 Heavy 10 and after seeing what I'm seeing I say stay away from grease. The PO of my Heavy 10 used grease almost everywhere. There is swarf and stringers caked up in the grease. Grease holds the chips. Oil, for the most part, moves them along. I've done so much reading on the grease-vs-oil debate my head's gonna pop. :banghead: A lot of guys are using the Type C oil with no problems for years. So with that I've decided to use Type C oil, applying it whenever I go to use the lathe, back gears or not.

i've got the head stock and drive gears reassemble and started oiling it up. Steve's manual recommends teflon grease for the spindle cone pulley and back gear shaft. The SB bulletin "Oiling the Lathe" suggests a few drops of oil in both of theses areas. What-s the best approach? If grease - how much

I'm in the process of reconditioning my 57 Heavy 10 and after seeing what I'm seeing I say stay away from grease. The PO of my Heavy 10 used grease almost everywhere. There is swarf and stringers caked up in the grease. Grease holds the chips. Oil, for the most part, moves them along. I've done so much reading on the grease-vs-oil debate my head's gonna pop. :banghead: A lot of guys are using the Type C oil with no problems for years. So with that I've decided to use Type C oil, applying it whenever I go to use the lathe, back gears or not.