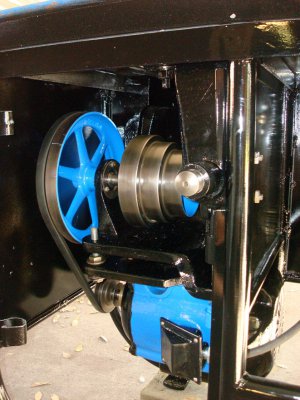

Happy New Yrs guys,todas a pretty good day for me and the SB.I devoted all day just on the headstock cleaning up and installing the spindle and the back gear.All went very well cause I took my time taking it apart and marking the brass shims which brings me to a question.I did install new felts with springs and oil everything down with spindle oil being careful putting the shims in the right place(so I thought).I do not have the spindle play adjusted yet(wait till its on the bed) but I do have the ring snug alittle which the spindle does not spin freely like the cone pulley.Will this loosen up some when I start to run it,or is there something else wrong?Guys before I started this project the spindle did spin good,so it was working.Now I'm second guessing myself thinking maybe I have a shim in the wrong place.That would be on the front cause one of the shims come loose from the bundle,maybe I have one in the wrong spot.Dang----kroll