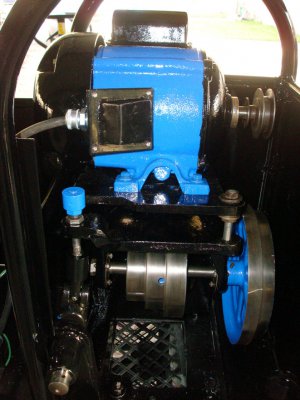

Guys yesterday afternoon the paint was drying so I decided to make a cover for the motor junction box,the original is MIA.The motor being alittle handycap since its a 3 footer and not 4 I just could not let it go necked with wires expose,so what do I have to lose other than time.

I found me apiece of 16ga metal,took some measurements of the cast iron back plate cut the metal to size allowing 3/16 over hang all the way around to bend over for a lip.Guys I'm sorry I can't keep a straight face.I watch "This Old House"and Tom Silva hollers out Cut off 3/16,it sounds so dramatic.Well the lip end up being what it is but its close to 3/16 or maybe its 1/4.

Guys I did luck off cause the lip that I bent using my torch and a piece of angle iron as a back plate in the vise work pretty good.

Using my bandsaw to cut out the parts for the cover and my die grinder with a cut off wheel to cut out the center piece except one end which I bent it up with the help of my torch.Then using the little mig welder,I spot the pieces in and tack them in place.The flap that I had left I heated it and then bent it over the side pieces then tack them in place.

Since my welding looks like a dirt dobber done it,I use the grinder to clean up the welds then check for holes and weld again.I will take my sanding disc and clean it up,then paint.Thanks for looking----kroll