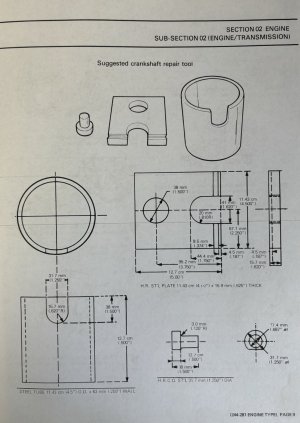

Hi, I’m new to this forum. I’m not a beginner machinist, I have run lathes, mills, surface grinders, etc, since I was in high school (late 70s early 80s). Worked in maintenance since late 80s. But I’ve never done enough of any machine work to get proficient at it. Just enough to get a job done. So I guess I’m a seasoned novice. I just received an old milling machine from another department at work to use at work. I also have a Grizzly G9729 mill, drill, lathe that I bought new about 20 years ago. I use it occasionally, it has got me out of some binds. I build vintage dirt bikes so it’s handy for that. I’m hoping to gain some knowledge on this forum with some up coming projects! Tonight I built a crankcase leak tester on my Grizzly. I still need to turn the other side for another size intake when I find out the size. I have the material to build the Rotax crankshaft press tools. Will need some advice on doing that!

Thanks!

Thanks!