- Joined

- Aug 5, 2018

- Messages

- 272

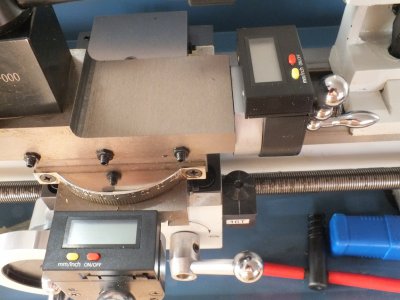

I have two machines I want to add DRO kits to, a Micromark mini lathe 84631 and their mini mill 84630.

Out of the crates they were both pretty rough but with some advice from you all and a project or two to tighten them up like adjustable brass gibs for the lathe carriage and scraping the compound and cross slide to eliminate chatter on the lathe and some work on the mill, they're in pretty good shape now.

All I need are DRO's for them.

LMS matches their kits to your machines but they are crazy expensive and what they have are magnetic.

Amazon has glass kits but it would be trial and error to find the right kit for my machines.

So, here are my questions:

Which is better magnetic or glass scales?

Is there somewhere other than LMS and Amazon where I can get what I need?

Lastly has anyone found a suitable match for the machines I have for their shop?

Mike.

Out of the crates they were both pretty rough but with some advice from you all and a project or two to tighten them up like adjustable brass gibs for the lathe carriage and scraping the compound and cross slide to eliminate chatter on the lathe and some work on the mill, they're in pretty good shape now.

All I need are DRO's for them.

LMS matches their kits to your machines but they are crazy expensive and what they have are magnetic.

Amazon has glass kits but it would be trial and error to find the right kit for my machines.

So, here are my questions:

Which is better magnetic or glass scales?

Is there somewhere other than LMS and Amazon where I can get what I need?

Lastly has anyone found a suitable match for the machines I have for their shop?

Mike.