Tmate - I think I'm looking to build the same general sized cut area you are using. You thread title of "CNC Plasma Cutting when you have no space" perfectly describes my situation. I have a garage full of great gear (Good sized, mill and lathe, Surface Grinder, small shaper, small cnc mill, work/wleding table with 1" steel top, welders and blowback start plasma cutter, surface plate and 3 mobile tool chests. So STUFF FOR AFRICA - lol.

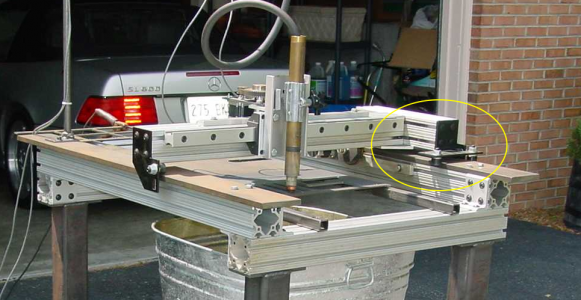

Sorry - back on topic, 24" (i.e. 600-610) cut area will be just fine. I am therefore roughly planning on X axis rails of about 1000mm (39.4") and a Y axis rail of about 750-800mm (29.5" to 31.5"). So if you know what your wheel spacing was (roughly) that would be rather useful. 10", 12" or something else?