- Joined

- Mar 26, 2018

- Messages

- 8,770

I learned something today.

While working on the fourth or fifth spindle and the second housing I made a big booboo.

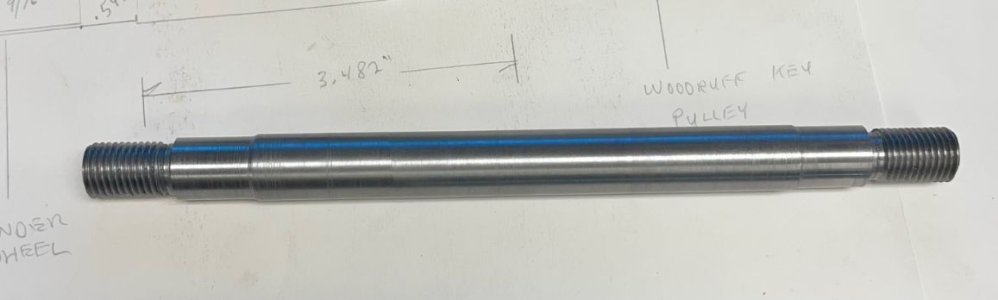

I'm turning between centers and threading 1/2" X 18. I was close so I removed the spindle from the lathe, tried a nut for fit and put it back on the lathe. I must have got the drive dog on a different jaw on the lathe.

Bad things happen

I'm learning.......

While working on the fourth or fifth spindle and the second housing I made a big booboo.

I'm turning between centers and threading 1/2" X 18. I was close so I removed the spindle from the lathe, tried a nut for fit and put it back on the lathe. I must have got the drive dog on a different jaw on the lathe.

Bad things happen

I'm learning.......