Let me start by saying I figured out the shielded control wiring thing. Nearly all of the panels I've seen are fairly simple and I couldn't wrap my head around why someone would use single conductor shielded MTW for the control wiring. Well, you wouldn't, but a multi-conductor cable with overall shield would be a really good thing which is what I believe the Yaskawa manual was on about. Any noise you can keep off of your single-ended signaling wires is a benefit. My narrow perspective made it more difficult to understand is all, lesson learned.

I've been doing a bunch more reading, there should be an mksj archive set up somewhere to house his prolific detailed documentation on the hundreds of projects he has helped people with so it's not all spread out. I think I have a fair understanding of the GA500 now (which arrived today) and the PM-1640TL (departed Omaha as of tonight, scheduled for delivery this Friday). There are a million ways to accomplish a VFD-based control system and it's easy to get caught up in what I call "Creeping Featurism", so for now I decided to shoot for a minimalist setup. That will get me up and running sooner rather than later, increase the odds that I won't run into space restrictions (I haven't laid eyes on the cabinet space yet), and allow me to gain some experience with the machine before I wander off down the rabbit hole of additional features. My goal is full safe operation of the machine as it would be from the factory if I had the right 3-phase power, and limit extra features unless they're almost more difficult to avoid implementing.

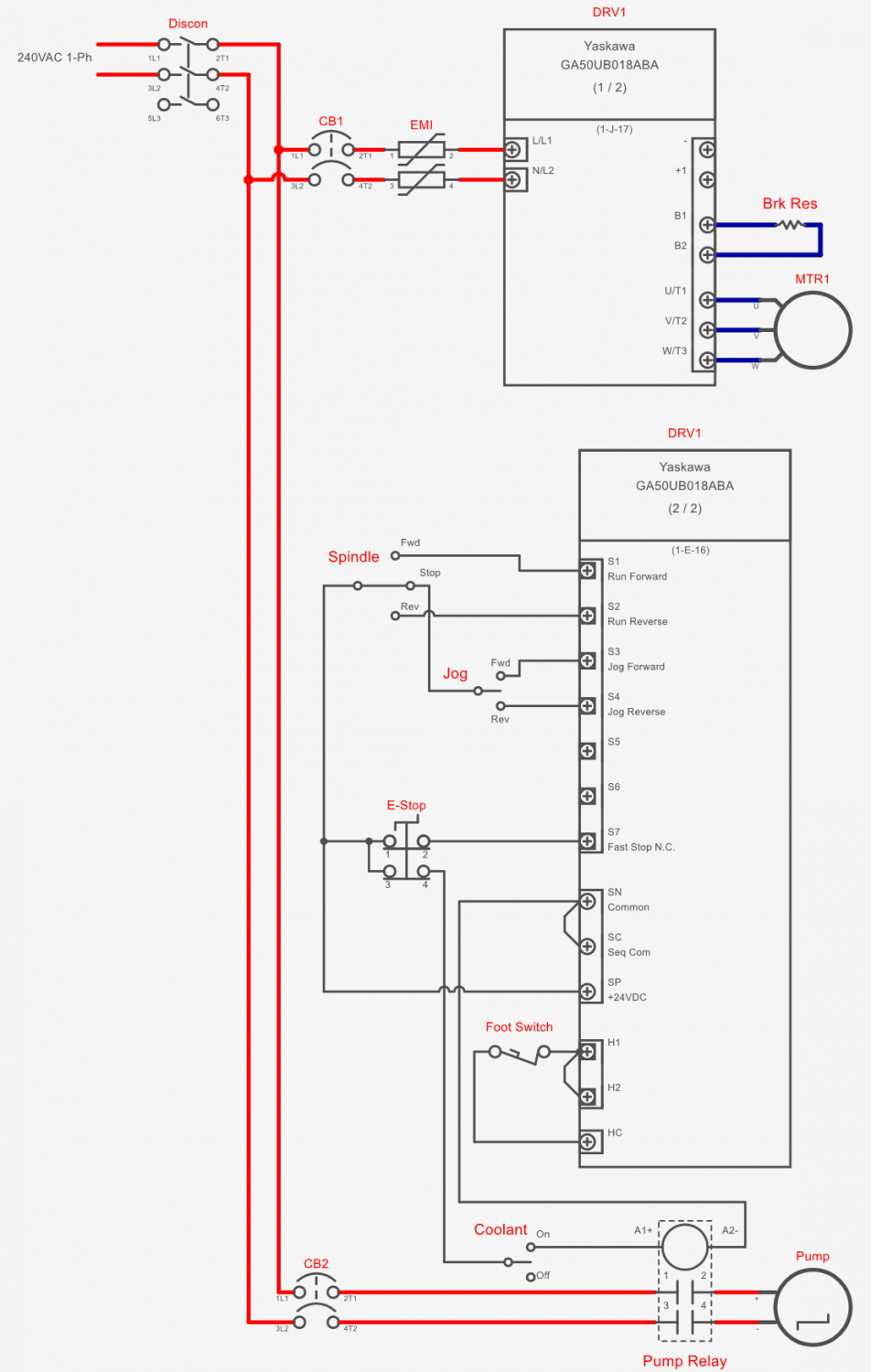

Objective defined, it was time to start with the diagrams to define the logic. My default option there is Altium Designer which I use for my PCB designs because I'm familiar with making symbols and schematics with it, but it's definitely not the right tool for control panel schematics. My searching around came up with a program called SkyCad out of Canada, which is PC based and has a free with registration license for un-professionals like me. It's not exactly what I'd call intuitive, as in sit down and crank out a schematic in an hour, but part of that is likely that I've never had to draw a diagram like this before and I still have difficulty understanding some of the symbols in the schematics I've seen so it's all new to me. The biggest issue I've had with it is there don't seem to be a lot of symbols defined for the types of components I'd need, which might be because I lean towards a whole relay as one component not a coil and individual sets of contacts spread out across multiple pages. Probably my fault. But they have some decent tutorial videos and once you get a handle on how to create a custom symbol you can make it what you want. It's what I'd call a little clunky compared to the other CAD software I've used, but overall it didn't crash on me and it looks like with some adjustments on my assumptions and some more experience it could be a decent way to produce simple control panel schematics. I'm not affiliated with SkyCad, I just figured I'd relate my experience so far in case any of you wanted to document your changes or builds and like me didn't have a good way of doing so. The very rough first draft I came up with:

My plan is from the disconnect, to one circuit breaker for the VFD and one for the coolant pump. The drive gets an EMI filter, which there was no symbol for and I didn't want to draw one up, so I just used a 2-pole surge suppressor symbol. The VFD has a built-in 24VDC supply with 150mA to spare. The DPDT power relay I'm eyeballing has a coil draw of 20mA max, and I believe the loss from the minimal wiring (18 AWG MTW or shielded cable equivalent) should keep me away from the limit, but that's TBD for sure. The jumper from SN to SC as shown put the drive in "Source" mode, meaning the external controls source the voltage (from the drive's power supply) to make an input active, and a lack of voltage makes an input inactive or off. The alternative "Sink" mode would mean connecting an input to the common (0VDC from the drive's supply) would make a contact on or active so it could go either way, but I lean towards positive logic instead of negative logic so that was my arbitrary choice barring any overriding reason others of you may know about that I don't yet. Incidentally the whole source and sink terminology gets confusing, it helps to look at the input and output diagrams in the manual and reference NPN and PNP transistor logic to make sure you get it right.

At power-up, even if the E-stop is not pushed (it's in its normally closed contact state) and the spindle is in the forward or reverse position, the drive will not start up and power the motor unless you specifically set that auto-restart option in the settings. The lever would need to be moved to the stop position to "remove the run command" in Yaskawa parlance, and only then would the drive recognize an additional run command. I could have provided that functionality with one relay that used the STOP signal from the lever to latch, but with the functionality already present and a minimalist objective in mind I don't see a reason to go there.

It seems like the intended design of the H1 and H2 safe torque off inputs (and associated HC common terminal) is to be connected to the E-stop, but that leaves the spindle to coast to a stop with no VFD braking, which isn't necessarily ideal in an emergency situation. The GA500 has a Fast Stop command that can be assigned to one of the seven digital inputs, with a deceleration time separate from the normal run/stop settings, that when activated will override any run command and aggressively brake the motor. There are actually two seperate fast stop commands, one Fast Stop Normally Open (N.O.) and Fast Stop Normally Closed (N.C.) that differ only in how "active" is defined. The N.O. command is active when +24V is applied to the input, causing a fast stop to be executed. The N.O. mode is not recommended by Yaskawa (not sure why it's even in there actually) because if for any reason there's a power supply glitch or the input circuitry on the drive goes wonky it's entirely feasible the drive may not "see" the command. They suggest the N.C. option, which is activated by the lack of +24V on the input, so is more fail-safe. +24VDC from the drive's supply is routed through one contact of the E-Stop to the S7 terminal which will be configured as the Fast Stop N.C. command, so smashing the big red button will stop the motor as fast as possible (after the time period is adjusted appropriately). The fast stop command will remain active until: the motor comes to a stop, the fast stop command is removed (made inactive) and all run commands are removed (made inactive, so move the lever to the stop position). Only then will the drive release from the stop mode and accept a new run command. This to me is acceptable behavior for the E-stop function. The creeping featurism here would be adding a safety relay which has instant acting contacts that will open when the E-stop is punched, and delayed contacts you can adjust to open a specified time after the initial contacts open. That would allow first applying the fast stop command, then waiting for say 1 or 2 (or 1.4) seconds and then applying the Safe Torque Off command through terminals H1 and H2. Technically that would be "safer" in case the drive went really nutz and didn't grok the fast stop command at all, and more levels of redundant safety are almost always better, but I'm leaving that for version two after I learn more about what else I may want to fiddle with.

While the H1/H2 safe torque off inputs aren't ideal for a simple E-stop scenario with a lathe, what they are ideal for is a lathe with a foot actuated brake that needs the VFD to back off immediately so it's not fighting with the mechanical brake the operator is stomping on vigorously. By running the HC terminal through the foot switch and jumpering H1 to H2, when the brake is not depressed H1 and H2 are connected to HC which is the normal run mode, you could call it Safe Torque Off N.C. When the brake switch is opened for 3ms or more, the drive overrides any run command and enters STO mode where power is removed from the motor which is then left to freewheel to a stop. Once activated, the STO mode will not release (exit, end) until all run commands have been cleared and the STO command on the H1 and H2 terminals is inactive. Note that disconnecting either of H1 or H2 from HC will activate the STO command, so the options are connect one of H1/H2 through the foot switch to common (HC) and the other of those terminals directly to HC, or jumper H1 and H2 together and common (HC) through the foot switch to either of them. Anybody got a coin to flip?

The GA500 has separate Jog Forward and Jog Reverse commands which may be assigned to one of the seven digital inputs. After all of the reading I've done I'm still not sure if the jog commands are considered run commands, or what would happen if you activated a jog command while the spindle was already running (especially if you tried to jog it in the other direction!). They didn't put in a paragraph covering that scenario for me, so it's one of the things I plan on very cautiously checking the functionality of. My idea for eliminating some of the ominous possibilities is to use a signal from the spindle control lever in the Stop position as the +24V source run through the jog swtich, so you can only issue a jog command when the lathe is stopped. That leaves the only question as whether or not you can jog the lathe while the E-stop is activated and the associated Fast Stop command. Maybe someone already knows, but I'll find out eventually and may need to adjust my strategy somewhat. Another reason to adopt the minimalist approach for now. Plus I have to find out if the switch setup on the spindle control can do that or if I need a different one or combination of switches.

For now I'm just going to use the on/off coolant switch that comes on the lathe to drive the coolant pump. I've never had a lathe with coolant capability before so I haven't really needed it, and I don't see a reason to add the automatic coolant-on functionality when the spindle is turning. Maybe I'd want that feature, maybe not. Minimalism and experience for the win again. The relay I have in mind is rated for 6a @ 250VAC, and the other designs I've seen have used overloead relays seet at 0.3A successfully so I'm thinking I'm okay with a relay instead of a contactor. It's easy enough to change if it turns out a contactor is better suited. Any words of wisdom with regard to contactors vs relays, I'd love to hear by the way. Oh, and since I was only using one set of contacts on he E-stop switch, by running the +24V through the second contact to the coolant on/off switch, the coolant relay won't activate unless the E-stop is in the run position, or said differently when you smack the red button the spindle AND the coolant pump will shut off.

As part of the minimalist dogma, I opted to not go with a potentiometer for variable speed control at this time. Odds are I'd leave it at the 60Hz mark most of the time anyway, and without a tach on the spindle which involves an encoder or magnets and a hall-effect sensor and a counter and a timer and a readout and so on (creeping featurism), it can be part of phase 2. For now I'll set the speed control to keypad instead of analog input, and just leave it at 60Hz.

I think that's about it, did I forget anything? I'm not 100% certain until I get hands on the lathe. Once I take out all of the existing control components, all I'll have in there is a disconnect, two circuit breakers, one EMI filter, the VFD and one relay. I believe that will be good enough to some good experience and daydream about the creeping featurism that's always looming just after the next project.

Comments, suggestions, witty rejoinders - all are appreciated.

Back to the drawing board,

-Doug

I've been doing a bunch more reading, there should be an mksj archive set up somewhere to house his prolific detailed documentation on the hundreds of projects he has helped people with so it's not all spread out. I think I have a fair understanding of the GA500 now (which arrived today) and the PM-1640TL (departed Omaha as of tonight, scheduled for delivery this Friday). There are a million ways to accomplish a VFD-based control system and it's easy to get caught up in what I call "Creeping Featurism", so for now I decided to shoot for a minimalist setup. That will get me up and running sooner rather than later, increase the odds that I won't run into space restrictions (I haven't laid eyes on the cabinet space yet), and allow me to gain some experience with the machine before I wander off down the rabbit hole of additional features. My goal is full safe operation of the machine as it would be from the factory if I had the right 3-phase power, and limit extra features unless they're almost more difficult to avoid implementing.

Objective defined, it was time to start with the diagrams to define the logic. My default option there is Altium Designer which I use for my PCB designs because I'm familiar with making symbols and schematics with it, but it's definitely not the right tool for control panel schematics. My searching around came up with a program called SkyCad out of Canada, which is PC based and has a free with registration license for un-professionals like me. It's not exactly what I'd call intuitive, as in sit down and crank out a schematic in an hour, but part of that is likely that I've never had to draw a diagram like this before and I still have difficulty understanding some of the symbols in the schematics I've seen so it's all new to me. The biggest issue I've had with it is there don't seem to be a lot of symbols defined for the types of components I'd need, which might be because I lean towards a whole relay as one component not a coil and individual sets of contacts spread out across multiple pages. Probably my fault. But they have some decent tutorial videos and once you get a handle on how to create a custom symbol you can make it what you want. It's what I'd call a little clunky compared to the other CAD software I've used, but overall it didn't crash on me and it looks like with some adjustments on my assumptions and some more experience it could be a decent way to produce simple control panel schematics. I'm not affiliated with SkyCad, I just figured I'd relate my experience so far in case any of you wanted to document your changes or builds and like me didn't have a good way of doing so. The very rough first draft I came up with:

My plan is from the disconnect, to one circuit breaker for the VFD and one for the coolant pump. The drive gets an EMI filter, which there was no symbol for and I didn't want to draw one up, so I just used a 2-pole surge suppressor symbol. The VFD has a built-in 24VDC supply with 150mA to spare. The DPDT power relay I'm eyeballing has a coil draw of 20mA max, and I believe the loss from the minimal wiring (18 AWG MTW or shielded cable equivalent) should keep me away from the limit, but that's TBD for sure. The jumper from SN to SC as shown put the drive in "Source" mode, meaning the external controls source the voltage (from the drive's power supply) to make an input active, and a lack of voltage makes an input inactive or off. The alternative "Sink" mode would mean connecting an input to the common (0VDC from the drive's supply) would make a contact on or active so it could go either way, but I lean towards positive logic instead of negative logic so that was my arbitrary choice barring any overriding reason others of you may know about that I don't yet. Incidentally the whole source and sink terminology gets confusing, it helps to look at the input and output diagrams in the manual and reference NPN and PNP transistor logic to make sure you get it right.

At power-up, even if the E-stop is not pushed (it's in its normally closed contact state) and the spindle is in the forward or reverse position, the drive will not start up and power the motor unless you specifically set that auto-restart option in the settings. The lever would need to be moved to the stop position to "remove the run command" in Yaskawa parlance, and only then would the drive recognize an additional run command. I could have provided that functionality with one relay that used the STOP signal from the lever to latch, but with the functionality already present and a minimalist objective in mind I don't see a reason to go there.

It seems like the intended design of the H1 and H2 safe torque off inputs (and associated HC common terminal) is to be connected to the E-stop, but that leaves the spindle to coast to a stop with no VFD braking, which isn't necessarily ideal in an emergency situation. The GA500 has a Fast Stop command that can be assigned to one of the seven digital inputs, with a deceleration time separate from the normal run/stop settings, that when activated will override any run command and aggressively brake the motor. There are actually two seperate fast stop commands, one Fast Stop Normally Open (N.O.) and Fast Stop Normally Closed (N.C.) that differ only in how "active" is defined. The N.O. command is active when +24V is applied to the input, causing a fast stop to be executed. The N.O. mode is not recommended by Yaskawa (not sure why it's even in there actually) because if for any reason there's a power supply glitch or the input circuitry on the drive goes wonky it's entirely feasible the drive may not "see" the command. They suggest the N.C. option, which is activated by the lack of +24V on the input, so is more fail-safe. +24VDC from the drive's supply is routed through one contact of the E-Stop to the S7 terminal which will be configured as the Fast Stop N.C. command, so smashing the big red button will stop the motor as fast as possible (after the time period is adjusted appropriately). The fast stop command will remain active until: the motor comes to a stop, the fast stop command is removed (made inactive) and all run commands are removed (made inactive, so move the lever to the stop position). Only then will the drive release from the stop mode and accept a new run command. This to me is acceptable behavior for the E-stop function. The creeping featurism here would be adding a safety relay which has instant acting contacts that will open when the E-stop is punched, and delayed contacts you can adjust to open a specified time after the initial contacts open. That would allow first applying the fast stop command, then waiting for say 1 or 2 (or 1.4) seconds and then applying the Safe Torque Off command through terminals H1 and H2. Technically that would be "safer" in case the drive went really nutz and didn't grok the fast stop command at all, and more levels of redundant safety are almost always better, but I'm leaving that for version two after I learn more about what else I may want to fiddle with.

While the H1/H2 safe torque off inputs aren't ideal for a simple E-stop scenario with a lathe, what they are ideal for is a lathe with a foot actuated brake that needs the VFD to back off immediately so it's not fighting with the mechanical brake the operator is stomping on vigorously. By running the HC terminal through the foot switch and jumpering H1 to H2, when the brake is not depressed H1 and H2 are connected to HC which is the normal run mode, you could call it Safe Torque Off N.C. When the brake switch is opened for 3ms or more, the drive overrides any run command and enters STO mode where power is removed from the motor which is then left to freewheel to a stop. Once activated, the STO mode will not release (exit, end) until all run commands have been cleared and the STO command on the H1 and H2 terminals is inactive. Note that disconnecting either of H1 or H2 from HC will activate the STO command, so the options are connect one of H1/H2 through the foot switch to common (HC) and the other of those terminals directly to HC, or jumper H1 and H2 together and common (HC) through the foot switch to either of them. Anybody got a coin to flip?

The GA500 has separate Jog Forward and Jog Reverse commands which may be assigned to one of the seven digital inputs. After all of the reading I've done I'm still not sure if the jog commands are considered run commands, or what would happen if you activated a jog command while the spindle was already running (especially if you tried to jog it in the other direction!). They didn't put in a paragraph covering that scenario for me, so it's one of the things I plan on very cautiously checking the functionality of. My idea for eliminating some of the ominous possibilities is to use a signal from the spindle control lever in the Stop position as the +24V source run through the jog swtich, so you can only issue a jog command when the lathe is stopped. That leaves the only question as whether or not you can jog the lathe while the E-stop is activated and the associated Fast Stop command. Maybe someone already knows, but I'll find out eventually and may need to adjust my strategy somewhat. Another reason to adopt the minimalist approach for now. Plus I have to find out if the switch setup on the spindle control can do that or if I need a different one or combination of switches.

For now I'm just going to use the on/off coolant switch that comes on the lathe to drive the coolant pump. I've never had a lathe with coolant capability before so I haven't really needed it, and I don't see a reason to add the automatic coolant-on functionality when the spindle is turning. Maybe I'd want that feature, maybe not. Minimalism and experience for the win again. The relay I have in mind is rated for 6a @ 250VAC, and the other designs I've seen have used overloead relays seet at 0.3A successfully so I'm thinking I'm okay with a relay instead of a contactor. It's easy enough to change if it turns out a contactor is better suited. Any words of wisdom with regard to contactors vs relays, I'd love to hear by the way. Oh, and since I was only using one set of contacts on he E-stop switch, by running the +24V through the second contact to the coolant on/off switch, the coolant relay won't activate unless the E-stop is in the run position, or said differently when you smack the red button the spindle AND the coolant pump will shut off.

As part of the minimalist dogma, I opted to not go with a potentiometer for variable speed control at this time. Odds are I'd leave it at the 60Hz mark most of the time anyway, and without a tach on the spindle which involves an encoder or magnets and a hall-effect sensor and a counter and a timer and a readout and so on (creeping featurism), it can be part of phase 2. For now I'll set the speed control to keypad instead of analog input, and just leave it at 60Hz.

I think that's about it, did I forget anything? I'm not 100% certain until I get hands on the lathe. Once I take out all of the existing control components, all I'll have in there is a disconnect, two circuit breakers, one EMI filter, the VFD and one relay. I believe that will be good enough to some good experience and daydream about the creeping featurism that's always looming just after the next project.

Comments, suggestions, witty rejoinders - all are appreciated.

Back to the drawing board,

-Doug

Last edited: