- Joined

- Jun 12, 2014

- Messages

- 5,071

The derating for a native 3 phase input VFD varies by manufacture and model, the 2X over sizing based on output amps under the rated conditions (variable torque, constant torque, ND, HD, other de-ratings) is a general rule. The Yaskawa drives it is 1.7X, and the addition of a DC buss choke reduces the current spikes to the capacitors that causes the increase THD when using single phase input. Yaskawa also indicates that a DC Buss choke is used in this application, but you will find that many if not most factory installed VFDs do not use them for these smaller drives. Since the manual lathe is almost never run at 100% load continuously, the actual amperage rating needed is less. So 14A x 1.7 = 23.8A for the GA50U2030ABA which should be fine. Nothing wrong with going with the GA50U2042ABA and/or not using a DC choke, but the input wiring and breaker rating typically would be larger/higher. I often end up using the 3 phase input VFD in a derated mode, I figure if one were to sell the machine at a later date it could be used with either 3 phase or single phase. A single phase input VFD only has a L1 and L2 inputs.

All the Yaskawa GA500/GA800/V1000 have a dc buss link should you chose to add a DC buss choke. The GA50UB018ABA is designed for single phase input, so a DC buss choke is not needed. A native single phase VFD is basically a larger 3 phase VFD running in a derated mode. The use of a DC choke does reduce the input fuse sizing for some VFDs, as well as the THD generated.

I have not seen an issue with VFD electrical interfernce issues with the higher end VFD's, with proper grounding and shielded cables. A DC choke and/or an input choke does decrease the line THD, I have only used a DC chokes in a few builds. In my own systems I do use an input EMI RFI mains filters but for no particular reason. I have yet to use a line reactor for the smaller VFD systems. Due to the size and cost of the line filters, nice if you have the room and want to spend the money, but not something I routinely use. If you do install one, then you want one specific for VFD use and the input current rating of the VFD.

Discussion on E-Stop function, I do not use typically use the STO in this application because it negates any VFD braking. The Yaskawa has a programable input for an E-Stop, which has a separate deacceleration rate as well as overiding any other run command and requiring all run commands to be removed before it will reset. If I were to use the STO, I probably would program the VFD output relay to engage at 0 speed and activate the STO. Haven't done this, since the intent is stop the machine as fast as possible and prevent accidental restart with release of the E-Stop. The latter is achieved by both programmed E-Stop input and the system control latching power relay which drops out in any fault mode. This can only be reset when the spindle switch is in the stop position, and also includes the foot brake application. An external braking resistor is required for fast stops and to prevnet buss over voltage errors. The Yaskawa also has different programable modes to prevent an over voltage error.

www.hobby-machinist.com

www.hobby-machinist.com

GA50UB018ABA install on the 1440C single phase input (not my VFD install)

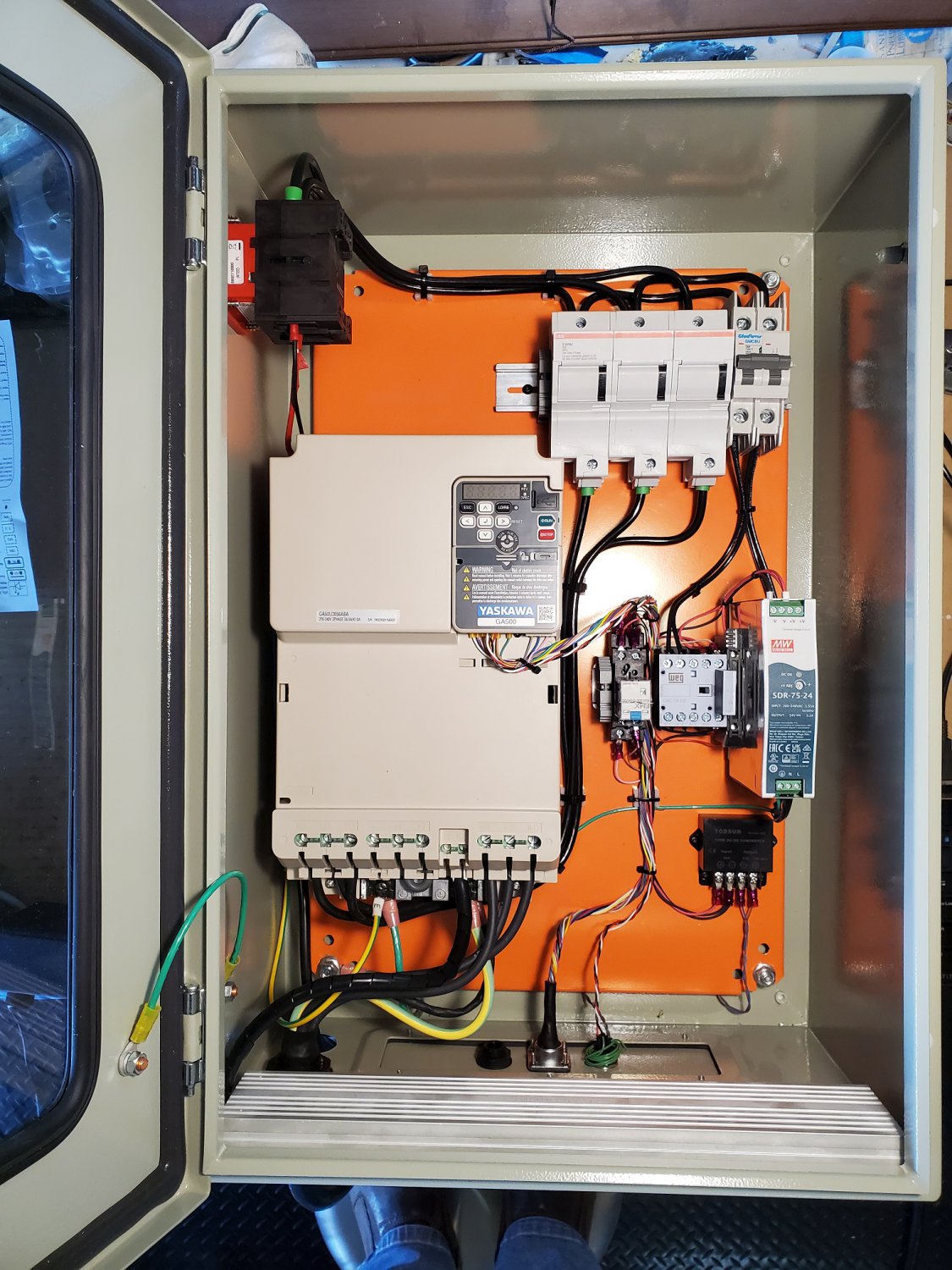

GA50U2056ABA install for a 10Hp motor, single phase or 3 phase input

All the Yaskawa GA500/GA800/V1000 have a dc buss link should you chose to add a DC buss choke. The GA50UB018ABA is designed for single phase input, so a DC buss choke is not needed. A native single phase VFD is basically a larger 3 phase VFD running in a derated mode. The use of a DC choke does reduce the input fuse sizing for some VFDs, as well as the THD generated.

I have not seen an issue with VFD electrical interfernce issues with the higher end VFD's, with proper grounding and shielded cables. A DC choke and/or an input choke does decrease the line THD, I have only used a DC chokes in a few builds. In my own systems I do use an input EMI RFI mains filters but for no particular reason. I have yet to use a line reactor for the smaller VFD systems. Due to the size and cost of the line filters, nice if you have the room and want to spend the money, but not something I routinely use. If you do install one, then you want one specific for VFD use and the input current rating of the VFD.

Discussion on E-Stop function, I do not use typically use the STO in this application because it negates any VFD braking. The Yaskawa has a programable input for an E-Stop, which has a separate deacceleration rate as well as overiding any other run command and requiring all run commands to be removed before it will reset. If I were to use the STO, I probably would program the VFD output relay to engage at 0 speed and activate the STO. Haven't done this, since the intent is stop the machine as fast as possible and prevent accidental restart with release of the E-Stop. The latter is achieved by both programmed E-Stop input and the system control latching power relay which drops out in any fault mode. This can only be reset when the spindle switch is in the stop position, and also includes the foot brake application. An external braking resistor is required for fast stops and to prevnet buss over voltage errors. The Yaskawa also has different programable modes to prevent an over voltage error.

Wiring Vevor VFD Control Panel in Remote Location

I just purchased a Vevor VFD for my lathe. It is a model A2-8075 - 7.5kw 10HP. The literature says the Smart Digital Display (control panel with stop/start and other push buttons plus LED display) can be removed from the VFD enclosure and mounted remotely. I downloaded the installation manual...

www.hobby-machinist.com

www.hobby-machinist.com

GA50UB018ABA install on the 1440C single phase input (not my VFD install)

GA50U2056ABA install for a 10Hp motor, single phase or 3 phase input