Opted to do a bit of CAD/CAM for the Eccentric Fixture. Not that is absolutely necessary, but it has been a good while since I've opened the program and I wanted the practice.

First I modeled the critical features for boring.

View attachment 363032

Next I modeled the piece of aluminum scrap I'm working with, including the randomly placed hole in it.

View attachment 363033

Additional features were added to help place the hold down fasteners

View attachment 363034

Locations for clamping washers are sketched in.

View attachment 363035

Clamping Bolt locations are drilled and Tapped. The central bore is expanded.

View attachment 363036

Gcode is written

View attachment 363044

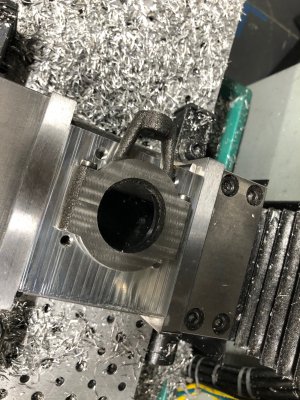

Finally, the fixture was machined. and hand tapped

View attachment 363065

View attachment 363066

View attachment 363068

Next step is to load the part onto the pallet and bore the hole.