- Joined

- Sep 7, 2019

- Messages

- 674

This is all great information! Thanks to everyone for sharing!

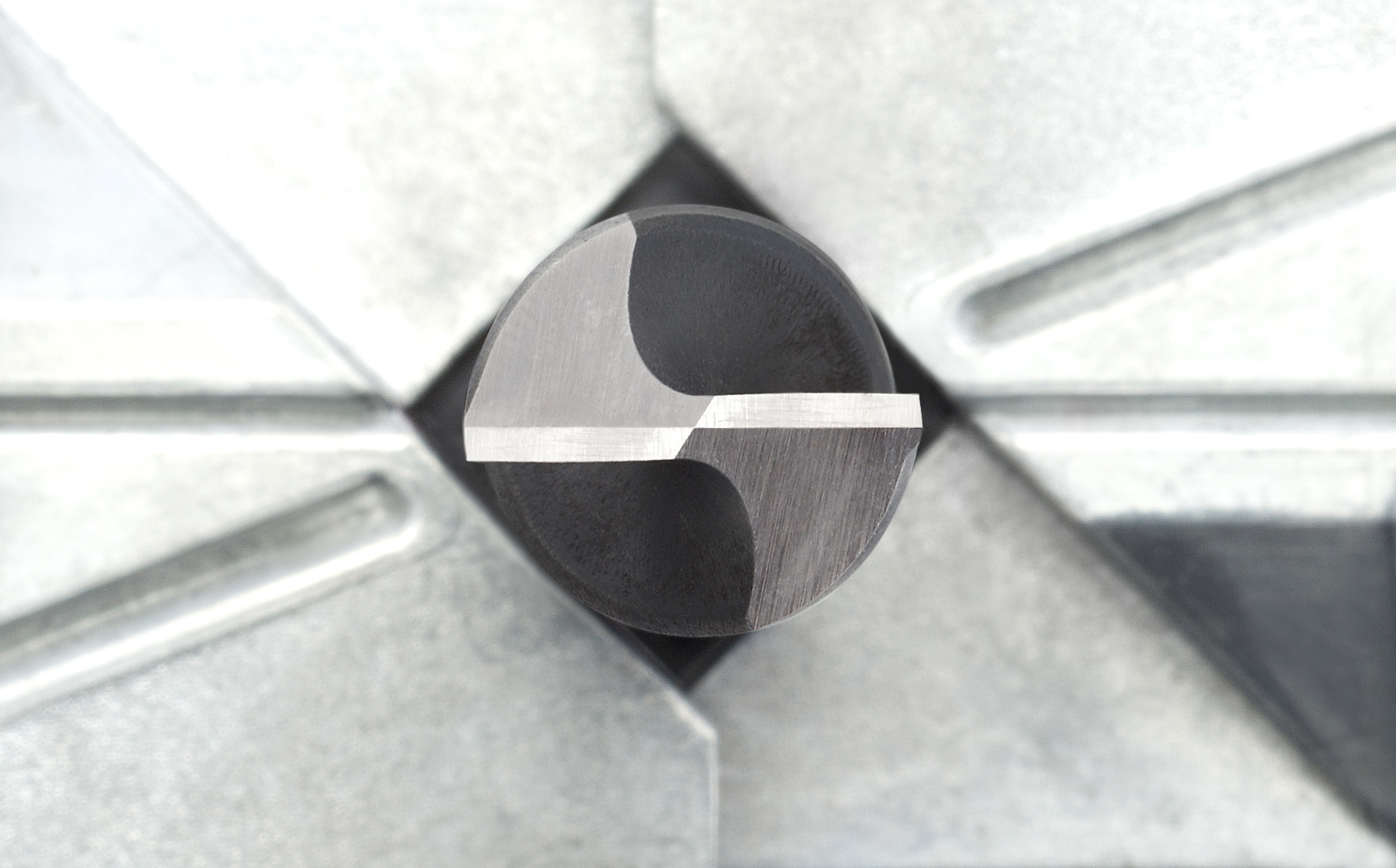

So if I understand the way this jig works, you'd grind a full sweep on each cutting edge with the minimum (recommended) drill bit extension, then you would reposition the jig a bit further AWAY from the grinding wheel and INCREASE the bit extension to meet the wheel. Then you would grind about 80% of the rear cutting edge. And you would end up with something like this...

Is that right?

Also if you first grind a full flatter clearance angle, then partially grind a tighter clearance angle (it helps to use a stop) you can create a 4 facet grind. I have done it and it works, but I did have to use a stop for accuracy of the secondary facet.

So if I understand the way this jig works, you'd grind a full sweep on each cutting edge with the minimum (recommended) drill bit extension, then you would reposition the jig a bit further AWAY from the grinding wheel and INCREASE the bit extension to meet the wheel. Then you would grind about 80% of the rear cutting edge. And you would end up with something like this...

Is that right?