-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's Talk Drill Bit Grinders!

- Thread starter Weldo

- Start date

- Joined

- Apr 23, 2018

- Messages

- 7,177

That's great information. I gather that the Cuttermaster and Drill Doctor are making modified split points? Which is great if you get the central chisel correct.

Robert

Grinder geometry and the degree of dress that is possible with the tool grinder wheel will dictate what you can do. It's a tough subject to get down into the weeds on, especially with the sea of nomenclature that's out there, but I think the split point you get with different setups comes down to three things.

1. Web thinning: Makes the bit pointy and accurate by reducing the contact area of the part of the tool that doesn't cut (the chisel or web).

2. Back cut and point splitting: Reduces wander by web thinning and increases chip clearance with the back cut in one step. This is what Cuttermaster and Drill Doctor are doing. It is a true split point, but not center-cutting.

3. Center cutting ability: Requires the grinding wheel to have a very crisp corner and a precise presentation angle in order to create a new cutting edge where the web approaches center. Instead of being close to center and square-ish, a true center cutting drill will have a complete cutting edge ground and relieved through the web and up to the center point, just like a symmetrical flute center-cutting 2-flute end mill.

For a hobbyist, chasing marginal gains has little in the way of payoff for the effort of splitting hairs, so this is all for fun. At least that's my take on it, and this is coming from a guy who has no qualifications other than liking to grind his own tools.

- Joined

- Jan 2, 2018

- Messages

- 605

It helps a lot to have a stop so the arc only goes 80%(for example) on both rear facets. I clamp a 123 block on the rest.This is all great information! Thanks to everyone for sharing!

So if I understand the way this jig works, you'd grind a full sweep on each cutting edge with the minimum (recommended) drill bit extension, then you would reposition the jig a bit further AWAY from the grinding wheel and INCREASE the bit extension to meet the wheel. Then you would grind about 80% of the rear cutting edge. And you would end up with something like this...

View attachment 313357

Is that right?

- Joined

- Jun 10, 2019

- Messages

- 542

- Joined

- Apr 28, 2014

- Messages

- 3,588

- Joined

- Sep 7, 2019

- Messages

- 674

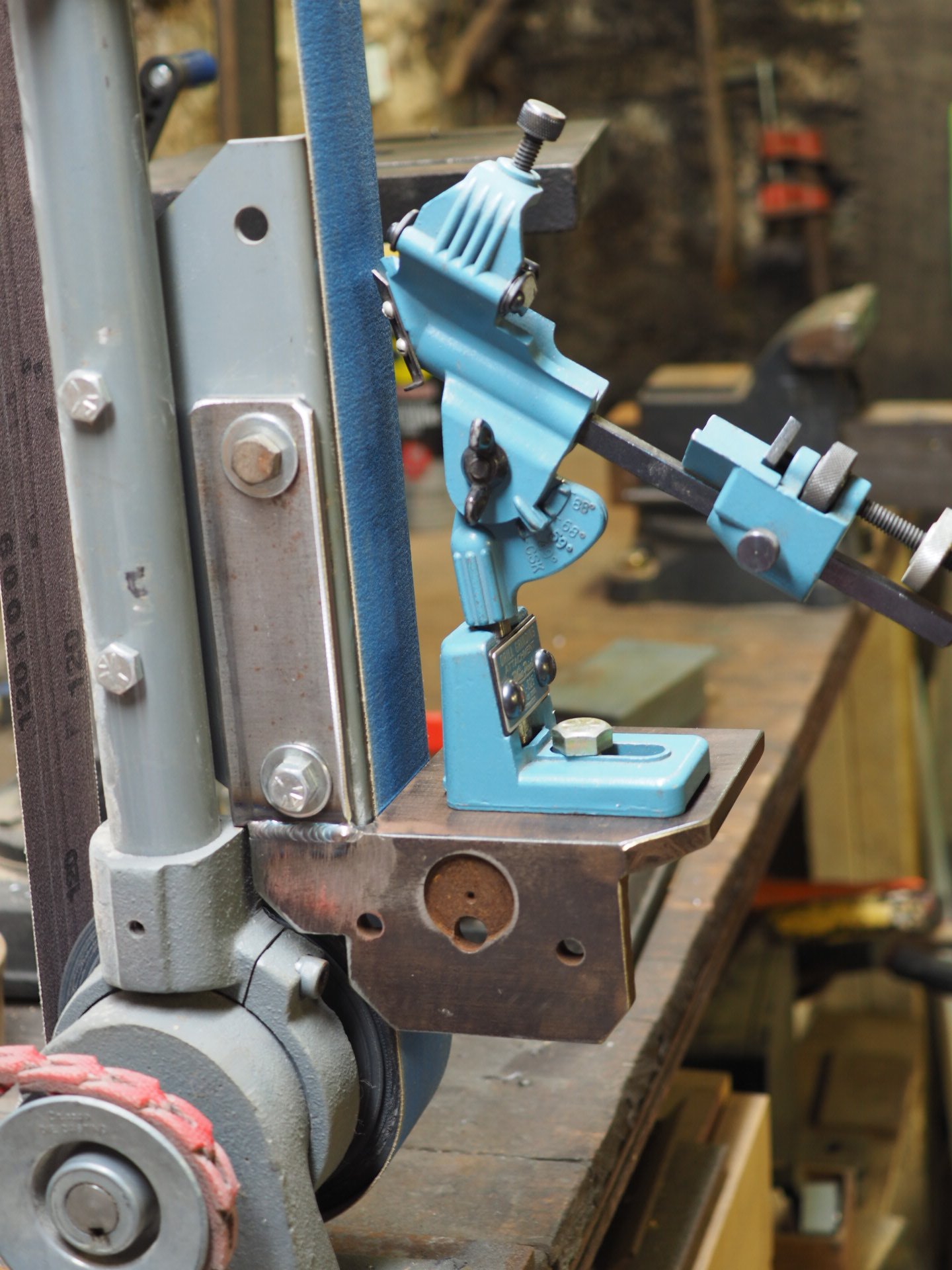

Got my Blue Point clone today!

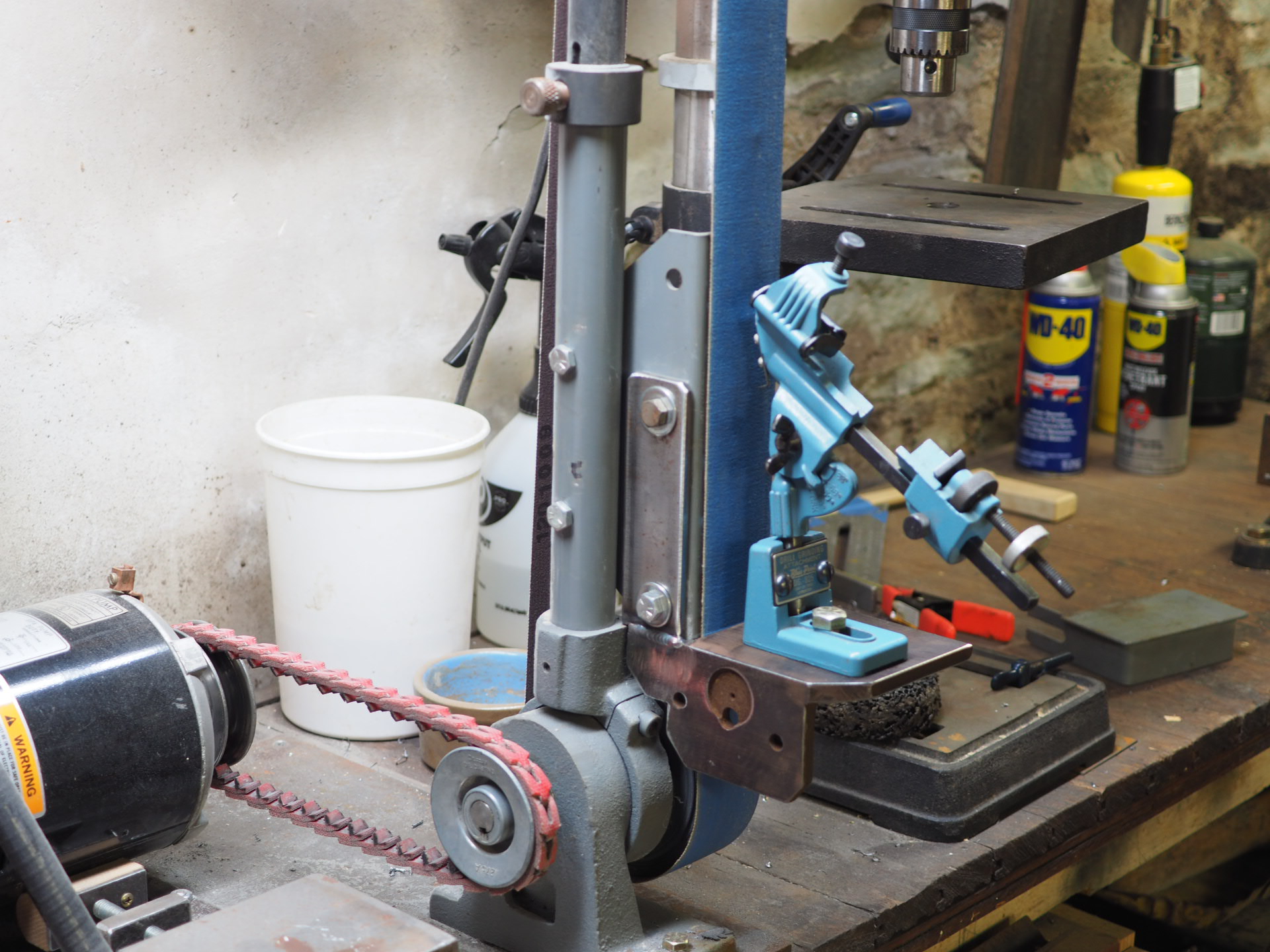

Spent two hours in the basement crafting a mount, check it out!

Here's the original tool rest. It's just sheet metal so it's got more flex than a drill grinder should have. Also it placed the drill tip almost off the platen.

Here's the mount I made. It's a 3/8" angle that someone years ago faced the two outside surfaces down to 5/16". I found this in a bucket with a bunch of misc. tools with my lathe. Can you believe I once contemplated throwing this in the scrap bin?! I welded a flat bar to give me some room for two bolts. All the holes in the big angle were existing. I thought of welding them up but didn't want to risk warpage. They don't harm nuthin'.

It mounts very solidly and perfectly square with two 5/16" - 18 bolts.

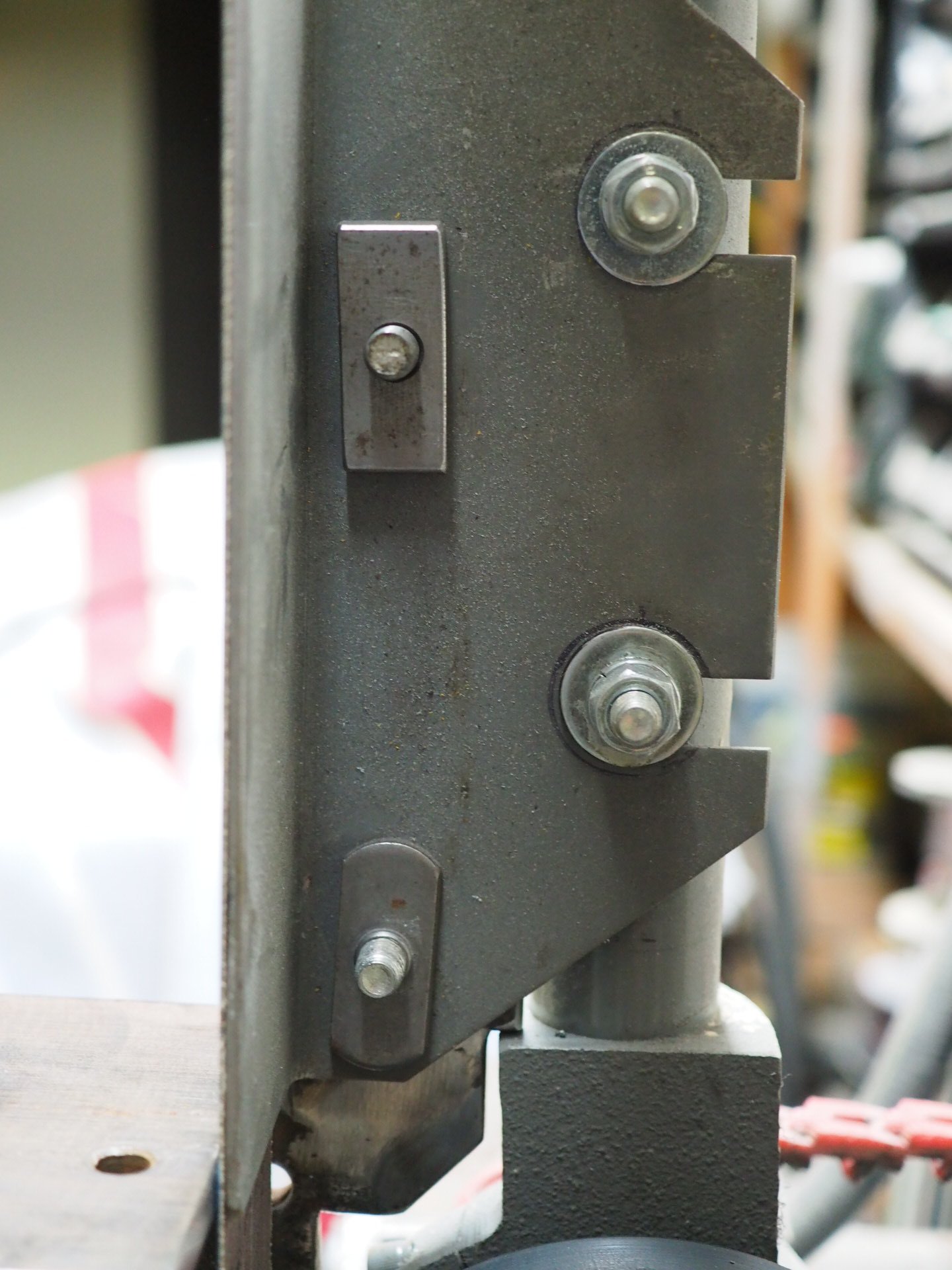

Here's how I bolted it. The lower one is a factory flow drilled and tapped piece. The upper one is a chunk of 1/4" flat bar, tapped. No wrench needed!

The following pics show the jig mounted. Instead of bolt and wing nut I just tapped the base for a 7/16-14 bolt.

Turned out pretty well. Haven't done a bit yet though. After working all day and then 2 hours on this I'm gonna relax for a while!

One question on the use of the jig. It says to stick the drill tip about 1/16" past the index tab, so to advance the drill into the grinding wheel are t you meant to use the threaded adjuster at the bit base? This will change the bit stick out slightly. Otherwise you'd have to move the whole jig until the bit made contact with the wheel, and that seems awkward...

Spent two hours in the basement crafting a mount, check it out!

Here's the original tool rest. It's just sheet metal so it's got more flex than a drill grinder should have. Also it placed the drill tip almost off the platen.

Here's the mount I made. It's a 3/8" angle that someone years ago faced the two outside surfaces down to 5/16". I found this in a bucket with a bunch of misc. tools with my lathe. Can you believe I once contemplated throwing this in the scrap bin?! I welded a flat bar to give me some room for two bolts. All the holes in the big angle were existing. I thought of welding them up but didn't want to risk warpage. They don't harm nuthin'.

It mounts very solidly and perfectly square with two 5/16" - 18 bolts.

Here's how I bolted it. The lower one is a factory flow drilled and tapped piece. The upper one is a chunk of 1/4" flat bar, tapped. No wrench needed!

The following pics show the jig mounted. Instead of bolt and wing nut I just tapped the base for a 7/16-14 bolt.

Turned out pretty well. Haven't done a bit yet though. After working all day and then 2 hours on this I'm gonna relax for a while!

One question on the use of the jig. It says to stick the drill tip about 1/16" past the index tab, so to advance the drill into the grinding wheel are t you meant to use the threaded adjuster at the bit base? This will change the bit stick out slightly. Otherwise you'd have to move the whole jig until the bit made contact with the wheel, and that seems awkward...

- Joined

- Mar 29, 2017

- Messages

- 748

Beautiful grind, and a no doubt SHARP drill. How many holes do you drill?. And you would end up with something like this...

Exactly. I have been making stuff, welding, nailing, cutting, brazing and soldering, drilling and bolting for 40 years around here. The 750 Drill Doctor cleans up my mess of "freehand" sharpening just fine. I have the patience, and no need to drill hundreds of holes/week in a production shop. "Marginal gains" is the operative idea.For a hobbyist, chasing marginal gains has little in the way of payoff for the effort of splitting hairs, so this is all for fun. At least that's my take on it, and this is coming from a guy who has no qualifications other than liking to grind his own tools.

I mean no disrespect. Sharp as razor drills, and machines and equipment to hold .0001 are a wonderful goal. Do we NEED that? Are you willing to spend the time and money to attain that? To what end?

I come from the construction trades. In that world, you learn very quickly that "If the customer likes it, and will pay for it, than that is good enough"

You can spend DAYS polishing a thing, and the Customer will not notice. I do not mean to imply that your plumber is looking to cut corners. I am merely saying that if the job calls for .01 tolerance, and the customer and situation demands no more, then why are you beating your head against the Shars Catalog chasing .0001? If your drill makes reasonably equal chips from each side, and does not SCREAM at you while you use it, is that not good enough for the Hobby Machinist?

- Joined

- Mar 17, 2018

- Messages

- 1,397

One question on the use of the jig. It says to stick the drill tip about 1/16" past the index tab, so to advance the drill into the grinding wheel are t you meant to use the threaded adjuster at the bit base? This will change the bit stick out slightly. Otherwise you'd have to move the whole jig until the bit made contact with the wheel, and that seems awkward...

I believe that is what they intend us to do. There aren't any micrometer dials on it, so just eyball everything. Once you start cutting, then you will want to carefully index both sides. Then sweep both sides the same way to get a drill thats cuts evenly.

You will figure it out quickly.

- Joined

- Apr 28, 2014

- Messages

- 3,588

No not really and yes that is enough, mainly - I would just like a little shop time!!!Beautiful grind, and a no doubt SHARP drill. How many holes do you drill?

Exactly. I have been making stuff, welding, nailing, cutting, brazing and soldering, drilling and bolting for 40 years around here. The 750 Drill Doctor cleans up my mess of "freehand" sharpening just fine. I have the patience, and no need to drill hundreds of holes/week in a production shop. "Marginal gains" is the operative idea.

I mean no disrespect. Sharp as razor drills, and machines and equipment to hold .0001 are a wonderful goal. Do we NEED that? Are you willing to spend the time and money to attain that? To what end?

I come from the construction trades. In that world, you learn very quickly that "If the customer likes it, and will pay for it, than that is good enough"

You can spend DAYS polishing a thing, and the Customer will not notice. I do not mean to imply that your plumber is looking to cut corners. I am merely saying that if the job calls for .01 tolerance, and the customer and situation demands no more, then why are you beating your head against the Shars Catalog chasing .0001? If your drill makes reasonably equal chips from each side, and does not SCREAM at you while you use it, is that not good enough for the Hobby Machinist?