Please explain, exactly what you do after the first pass. I'm trying to understand everything you did, don't leave a single boring detail out, right down to scratching your nose. Do you disengage anything besides the half nuts?

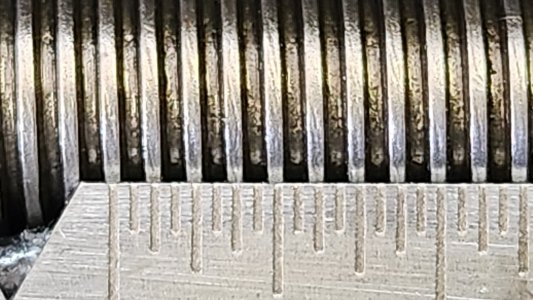

On the last picture, on the bottom gears, the middle one, there's another gear on the middle shaft? Can you take a picture of that? Also, your lead screw, can you show a detail of the section, do the threads look sharp, or flat topped? The picture may be playing tricks on my eyes, so it would be good to get another, closer view.

One thing that is interesting is the second thread is not exactly in the middle of the original thread. It's closer to a third. If you do a third pass, does it shift further and fill in the blank area? Or are the thread starts more random, rather than simply linear offset?