Tailstock4 and epanzella, were correct, their process worked. I owe you a beer.

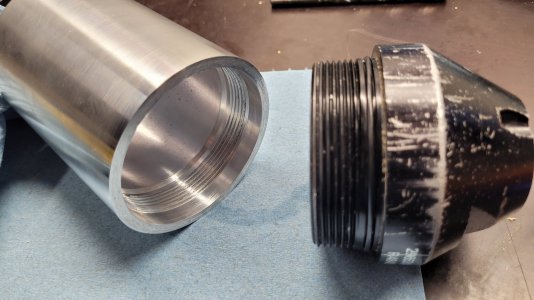

The threads were a little fugly, but the mating part (which i was unable to covert to imperial) threaded in just fine and the O-ring should seal.

Many thanks for getting me out of this jam. This was a big customer (household name) and there was no way i was gonna turn them away.

I just got a used Haas TM-1...i think its time to figure out thread milling...

Thanks again fellas (mine are the aluminum threads on the left)