- Joined

- Oct 16, 2024

- Messages

- 8

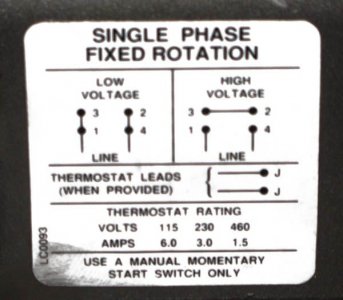

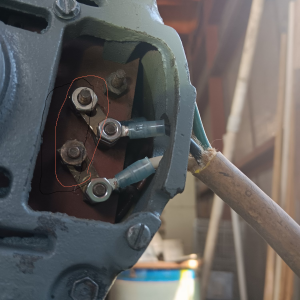

I recently bought a Craftsman/Atlas lathe with a 1hp Baldor dual voltage motor on it. It had a 110v plug on it when I bought it. After finally being able to read the data tag I was able to confirm it was dual voltage. Since all the equipment in my shop runs n 220v I thought I would convert it also After lots of searching I thought I had found a diagram that was correct. But when I started it on 220v it growls and vibrates . It is an older motor so I'm not sure if I have it wired right or not. It does run fine on 110v. I have searched the net but not found anything with this problem. Any help??

Last edited:

![20241122_110201[1].jpg](/data/attachments/467/467872-cce2b473e16a0886424529abba5c0df9.jpg?hash=MYQH5vkrMl)

![20241122_105940[1].jpg](/data/attachments/467/467873-288aa5f4303742e44286f6c5d7a36b78.jpg?hash=mnvHWhXGwx)