Heck yeah this looks great. I would love to have the spreadsheet. Thanks.@Ischgl99

I could not get your spread sheet to work right for me. I think I can fix it later.

@LROYSON

I looked at the manual some more. It appears that the exchange gear is a different size axle and it is threaded. But it does also take a 56T.

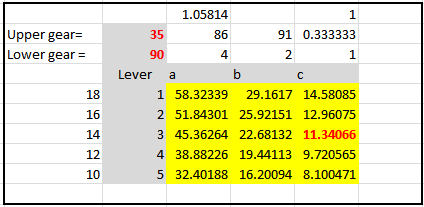

So I ran my Excel work book based upon the info I could find and I generated the following possibilities for you.

In this table when letters appear in two columns it means that you can use any gear at this location. The Screw2C column is the bottom axle gear position and the Spindle column is the upper gear axle. Looks like you have several possibilities to get close to 11.5TPI. But I will try to take a closer look at this later. If you agree then I can post the entire spread sheet for you.

View attachment 448294

Dave L.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting 11.5 TPI threads

- Thread starter LROYSON

- Start date

Hi @Ischgl99

I was surprised that I did not get your table to work as I know you are very good at this process. Anyway,....

I agree, it seemed simple, but maybe I missed something the first time through it as I was rushing. I think I was confused by the 30T gear showing up but not the 90T gear to establish the initial TIP values. Hence, I thought I was suppose to change gear tooth number where you had placed the number 52. So I did so as a check. I thought that if I put it to the standard 90T gear that I should get the original table back, but instead the "one-a" entry is 24 not 76. This, now, is obviously not what you wanted me to do. So just now, I changed the 52T number to 30 and the original TPI values appeared. No where in the table was there a place to change the gear box gear, 90T. Maybe you had built this into the initial gear ratios you had placed in column A and so it was not so obvious. Anyway, I did not understand earlier but think I understand now. Your spread sheet works!

So recreated your table, but some what differently so that the ratios were increasing as the knob was turned from one to five. In my version of your table I put the gear ratios as decreasing with knob number rather than increasing. I did this because the TPI in the first column was also decreasing as one does down the column of the table. I also used integers rather than fractions. I put the additional fractional relationship, 1/3 at the top of the table. The gear number and the ratio to make it all fit was 1/3. Then I added the possibility of using the exchange gears, 89, 91, and 56 at the top. I also added what appears to be an unimportant 1 on the Imperial tables, but when you turn to the Metric page you will see that 25.4 is included to make this conversion.

Then when I changed the 30T to 52T as you suggested. I got the Five-B to yield 11.53846TPI, in agreement with your spread sheet. It is even more ironic that if I change the Upper gear to 30 and the lower gear to 52 we get 11.55556! But maybe in this arrangement it is physically impossible to get all of the gears to touch???

Anyway, in the spread sheet that I am attaching I repeated a few of these tables so that one can try out upper and lower gears for each table and compare them. I also added the metric sheet. Note, that I set one of these up to yield 1.5mm/T and we see that it is an approximation because of the 91/86 is not quite exact. If you replace the 91 with 127 and the 86 with 120 the metric threads come out even, 1.5mm/T.

Good night.

Dave L.

I was surprised that I did not get your table to work as I know you are very good at this process. Anyway,....

I agree, it seemed simple, but maybe I missed something the first time through it as I was rushing. I think I was confused by the 30T gear showing up but not the 90T gear to establish the initial TIP values. Hence, I thought I was suppose to change gear tooth number where you had placed the number 52. So I did so as a check. I thought that if I put it to the standard 90T gear that I should get the original table back, but instead the "one-a" entry is 24 not 76. This, now, is obviously not what you wanted me to do. So just now, I changed the 52T number to 30 and the original TPI values appeared. No where in the table was there a place to change the gear box gear, 90T. Maybe you had built this into the initial gear ratios you had placed in column A and so it was not so obvious. Anyway, I did not understand earlier but think I understand now. Your spread sheet works!

So recreated your table, but some what differently so that the ratios were increasing as the knob was turned from one to five. In my version of your table I put the gear ratios as decreasing with knob number rather than increasing. I did this because the TPI in the first column was also decreasing as one does down the column of the table. I also used integers rather than fractions. I put the additional fractional relationship, 1/3 at the top of the table. The gear number and the ratio to make it all fit was 1/3. Then I added the possibility of using the exchange gears, 89, 91, and 56 at the top. I also added what appears to be an unimportant 1 on the Imperial tables, but when you turn to the Metric page you will see that 25.4 is included to make this conversion.

Then when I changed the 30T to 52T as you suggested. I got the Five-B to yield 11.53846TPI, in agreement with your spread sheet. It is even more ironic that if I change the Upper gear to 30 and the lower gear to 52 we get 11.55556! But maybe in this arrangement it is physically impossible to get all of the gears to touch???

Anyway, in the spread sheet that I am attaching I repeated a few of these tables so that one can try out upper and lower gears for each table and compare them. I also added the metric sheet. Note, that I set one of these up to yield 1.5mm/T and we see that it is an approximation because of the 91/86 is not quite exact. If you replace the 91 with 127 and the 86 with 120 the metric threads come out even, 1.5mm/T.

Good night.

Dave L.

Attachments

@LROYSON

I will see if I can check the spread sheet out in the light of day and then if it still looks ok I will post it at the thread I mentioned earlier.

Dave L.

I will see if I can check the spread sheet out in the light of day and then if it still looks ok I will post it at the thread I mentioned earlier.

Improved Version: TPI, Feeds, X-Feeds: Generalized Lathe TPI Excel file: "TPI_ManyLathesRev1 N502_1630"

Dave L.

I guess I wasn’t clear on that part, I was only changing the top gear to keep it simple, and didn’t expand it to changing the bottom gear since there were a few combinations that worked. Also, since the lathe comes with 30 and 60 tooth gears, anything between those two should easily fit in there, and by going below or above that may cause installation issues.Hi @Ischgl99

I was surprised that I did not get your table to work as I know you are very good at this process. Anyway,....

I agree, it seemed simple, but maybe I missed something the first time through it as I was rushing. I think I was confused by the 30T gear showing up but not the 90T gear to establish the initial TIP values. Hence, I thought I was suppose to change gear tooth number where you had placed the number 52. So I did so as a check. I thought that if I put it to the standard 90T gear that I should get the original table back, but instead the "one-a" entry is 24 not 76. This, now, is obviously not what you wanted me to do. So just now, I changed the 52T number to 30 and the original TPI values appeared. No where in the table was there a place to change the gear box gear, 90T. Maybe you had built this into the initial gear ratios you had placed in column A and so it was not so obvious. Anyway, I did not understand earlier but think I understand now. Your spread sheet works!

So recreated your table, but some what differently so that the ratios were increasing as the knob was turned from one to five. In my version of your table I put the gear ratios as decreasing with knob number rather than increasing. I did this because the TPI in the first column was also decreasing as one does down the column of the table. I also used integers rather than fractions. I put the additional fractional relationship, 1/3 at the top of the table. The gear number and the ratio to make it all fit was 1/3. Then I added the possibility of using the exchange gears, 89, 91, and 56 at the top. I also added what appears to be an unimportant 1 on the Imperial tables, but when you turn to the Metric page you will see that 25.4 is included to make this conversion.

Then when I changed the 30T to 52T as you suggested. I got the Five-B to yield 11.53846TPI, in agreement with your spread sheet. It is even more ironic that if I change the Upper gear to 30 and the lower gear to 52 we get 11.55556! But maybe in this arrangement it is physically impossible to get all of the gears to touch???

Anyway, in the spread sheet that I am attaching I repeated a few of these tables so that one can try out upper and lower gears for each table and compare them. I also added the metric sheet. Note, that I set one of these up to yield 1.5mm/T and we see that it is an approximation because of the 91/86 is not quite exact. If you replace the 91 with 127 and the 86 with 120 the metric threads come out even, 1.5mm/T.

Good night.

Dave L.

Heck yeah this looks great. I would love to have the spreadsheet. Thanks@Ischgl99

I could not get your spread sheet to work right for me. I think I can fix it later.

@LROYSON

I looked at the manual some more. It appears that the exchange gear is a different size axle and it is threaded. But it does also take a 56T.

So I ran my Excel work book based upon the info I could find and I generated the following possibilities for you.

In this table when letters appear in two columns it means that you can use any gear at this location. The Screw2C column is the bottom axle gear position and the Spindle column is the upper gear axle. Looks like you have several possibilities to get close to 11.5TPI. But I will try to take a closer look at this later. If you agree then I can post the entire spread sheet for you.

View attachment 448294

Dave L.

Ok so I set my top gear to 35t swapped the middle gear from 91t to 86t and bottom gear is still 90t. I ran a scratch pass and the gage is so close to 11.5 it is almost indiscernible. It must be 11.49 or something really close to it. I have some work to do to setup and make the thread but I think it may work.

- Joined

- Feb 17, 2013

- Messages

- 4,418

A possible solution to the problem, not requiring fabrication or installation of additional gears, is described in the November/December issue of _The Home Shop Machinist_, pages 8-21.

The article is by Herb Yohe, and is entitled "Any Thread: A Parallel-linked, Adjustable Sine Bar Threading Attachment." The author's lathe is a 12" Powermatic Logan, and the attachment looks like it could be adapted to work with just about any lathe.

You can order back issues of HSM at https://secure.villagepress.com/store/items/list/group/775

The article is by Herb Yohe, and is entitled "Any Thread: A Parallel-linked, Adjustable Sine Bar Threading Attachment." The author's lathe is a 12" Powermatic Logan, and the attachment looks like it could be adapted to work with just about any lathe.

You can order back issues of HSM at https://secure.villagepress.com/store/items/list/group/775

Hi @LROYSON

Well that is good to hear. But I don't think that was one that I recommended.!!?

The earlier posting that I provided where I suggested you put the exchange at the lower position was in error as I found in the manual that the exchange gears will not fit on the other axles. https://www.hobby-machinist.com/threads/cutting-11-5-tpi-threads.106322/post-1042758

However, I have taken the time this morning to work through my workbook and get your lathe incorporated in to it. I will post it after I complete this posting.

So is this what you just said you had set up. Upper gear: 35T, Lower gear: 90T, exchange gears 91/86. If so then I think these are the possible thread values. This table came from the excel sheet I put on your string last night.

I think you can get even closer than this if you try either of the following set ups. Does your lathe allow you to attache the 56/91 pair at the exchange gear location? I think it should but the manual is not clear.

Please let me know if you down load the files I am going to post at my threading string. If you have any questions about how to put them together or to run the macros I will be glad to try to help.

Dave L.

Well that is good to hear. But I don't think that was one that I recommended.!!?

The earlier posting that I provided where I suggested you put the exchange at the lower position was in error as I found in the manual that the exchange gears will not fit on the other axles. https://www.hobby-machinist.com/threads/cutting-11-5-tpi-threads.106322/post-1042758

However, I have taken the time this morning to work through my workbook and get your lathe incorporated in to it. I will post it after I complete this posting.

So is this what you just said you had set up. Upper gear: 35T, Lower gear: 90T, exchange gears 91/86. If so then I think these are the possible thread values. This table came from the excel sheet I put on your string last night.

I think you can get even closer than this if you try either of the following set ups. Does your lathe allow you to attache the 56/91 pair at the exchange gear location? I think it should but the manual is not clear.

Please let me know if you down load the files I am going to post at my threading string. If you have any questions about how to put them together or to run the macros I will be glad to try to help.

Re: Improved Version: TPI, Feeds, X-Feeds: Generalized Lathe TPI Excel file: "TPI_ManyLathesRev1 N502_1630"

Dave L.

So you are calling the middle gear the exchange gear correct? That is the gear that I originally had 86 on the outside (not in contact with any gears) and 91 on the inside (in contact on upper gear and lower gear). I should he able to put the 56t on the inside of the exchange and 30t on top and 91t on bottom withgear box in b2 to get 11.487 correct, or 49t on top 91t on inside of exchange 86t in bottom with gear box in b2 position to get 11.51tpi correct? I had an issue getting to you original post can you give me the link to it here. Is it a zip file and after I download and unzip them what do I run?

Hi, @LROYSON

Yes, the middle axle, where the gears thread on is the Exchange Gear Position. It is the one where two gears are located and one sets on top of the other. The other gears Upper(Top, near the spindle) and Lower (bottom at the gear box) are simply called the external gears. The upper and lower gears contact just one of the exchange gears (normal imperial threading operation), or one contacts one of the exchange gears while the other contacts the other of this pair (usually for metric). When the upper and lower gears contacts the same middle exchange gear it can be any number of teeth as it is just transferring the rotation and not changing the ratios at all. So any single center gear will yield the same TPI value! When different exchange gears of the pair are being contacted separately then you will get a different TPI value. The standard Metric arrangement for your lathe has the 91 tooth gear in contact with the upper gear(30T) and the 86T in contact with the lower gear (90T). I have tried to explain this in more detail in my other post. Simply put, with the larger exchange gear is in contact with the upper (spindle) gear the TPI value will be larger. Flip the order of the exchange gears and the TPI value will be smaller.

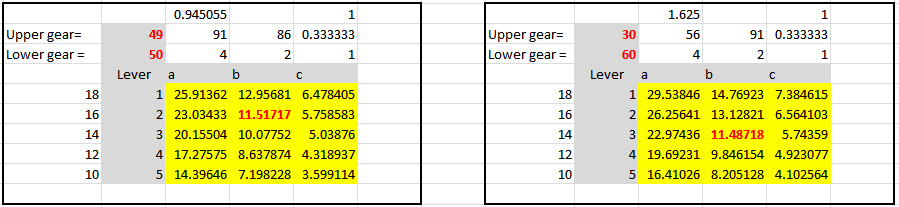

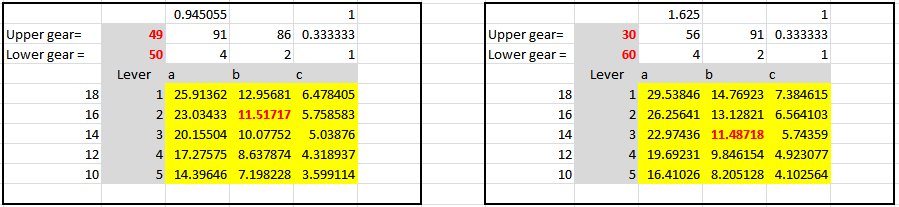

So in the two table I posted bit ago, and repeat below) it is not so obvious how the gears are arranged. Sorry about that. Upper and Lower are clear by the equal sign. In these tables below the upper gear would be contacting the exchange gear immediatly to the right of the upper gear value. (30 touches 56) Likewise, the lower gear touches the second exchange gear listed farther to the right (60 touches 91). This yields the 11.487 TPI value. Likewise in the other table the upper gear = 49 touches 91 and the lower gear = 50, touches 86 to yield the 11.517TPI.

The zip file is at

The macro enabled file to be used is in the very first posting and is the one you should download and unzip. The new sheet for your lathe I just posted with instructions on how to install it in the unzipped workbook. If you do not understand how to do this I will fix it up for you and send it directly to you.

Regards,

Dave L.

Yes, the middle axle, where the gears thread on is the Exchange Gear Position. It is the one where two gears are located and one sets on top of the other. The other gears Upper(Top, near the spindle) and Lower (bottom at the gear box) are simply called the external gears. The upper and lower gears contact just one of the exchange gears (normal imperial threading operation), or one contacts one of the exchange gears while the other contacts the other of this pair (usually for metric). When the upper and lower gears contacts the same middle exchange gear it can be any number of teeth as it is just transferring the rotation and not changing the ratios at all. So any single center gear will yield the same TPI value! When different exchange gears of the pair are being contacted separately then you will get a different TPI value. The standard Metric arrangement for your lathe has the 91 tooth gear in contact with the upper gear(30T) and the 86T in contact with the lower gear (90T). I have tried to explain this in more detail in my other post. Simply put, with the larger exchange gear is in contact with the upper (spindle) gear the TPI value will be larger. Flip the order of the exchange gears and the TPI value will be smaller.

So in the two table I posted bit ago, and repeat below) it is not so obvious how the gears are arranged. Sorry about that. Upper and Lower are clear by the equal sign. In these tables below the upper gear would be contacting the exchange gear immediatly to the right of the upper gear value. (30 touches 56) Likewise, the lower gear touches the second exchange gear listed farther to the right (60 touches 91). This yields the 11.487 TPI value. Likewise in the other table the upper gear = 49 touches 91 and the lower gear = 50, touches 86 to yield the 11.517TPI.

The zip file is at

Improved Version: TPI, Feeds, X-Feeds: Generalized Lathe TPI Excel file: "TPI_ManyLathesRev1

The macro enabled file to be used is in the very first posting and is the one you should download and unzip. The new sheet for your lathe I just posted with instructions on how to install it in the unzipped workbook. If you do not understand how to do this I will fix it up for you and send it directly to you.

Regards,

Dave L.

Similar threads

- Replies

- 87

- Views

- 8K

- Replies

- 44

- Views

- 2K

- Replies

- 35

- Views

- 1K