- Joined

- Jan 6, 2017

- Messages

- 1,250

That's what I'm thinking also. My friend said he would make one for me with his 3D printer. I don't really have that much of a need for one that would justify an expensive gear. It's going to be interesting how long a plastic gear will last.

I was going to make a custom hose end for my wintertime stock tank hose. It's kind of a long story but basically every time I add water to the stock tank I have to connect and disconnect a hose. With the currently available hose ends it gets a little tough with gloves on. So, I thought I would make one that was glove friendly.

Another option would be for me to learn to make gears and make my own. That might take a while though since I'm still trying to learn all the nomenclature as it is.

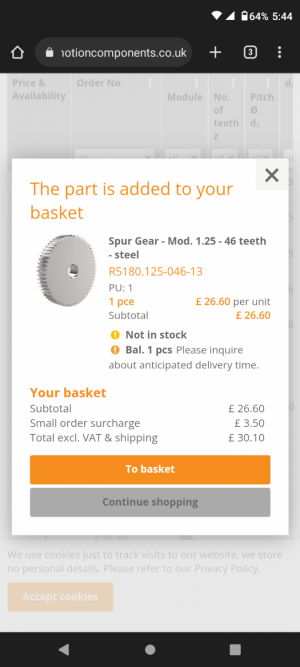

If you can't find anything else and don't mind ordering from the UK:

It's 13mm thick and has a 12mm bore.

You'd have to face 3mm off, bore the hole to 18mm then cut a 5mm keyway.

26 Euros + whatever shipping from the UK.

And of course, not currently in stock.

R5180 - Spur Gears - Module 1.25

R5180 Spur Gears - Module 1.25; Free CAD models available online.

Attachments

Last edited: