Hello guys, I hope this finds you all well.

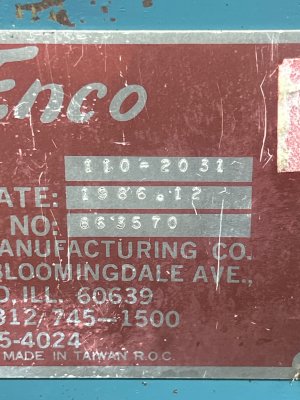

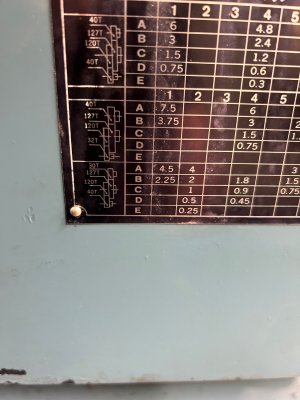

Got a question about my enco 12x36 lathe. This lathe is a Taiwanese lathe from the 80s that was branded as various brands so this may not be specific to Enco. Question is on the back of my lathe there seems to be only one change gear that gets flipped if need be. It came on my machine ready to go however I read somewhere that there may be others that came with my machine but got lost somewhere along the way. Is there other gears or a gear that I’m missing? Grizzly shows one for the G9249 but I’m looking to see if it’s actually my missing gear. Thanks in advance

Got a question about my enco 12x36 lathe. This lathe is a Taiwanese lathe from the 80s that was branded as various brands so this may not be specific to Enco. Question is on the back of my lathe there seems to be only one change gear that gets flipped if need be. It came on my machine ready to go however I read somewhere that there may be others that came with my machine but got lost somewhere along the way. Is there other gears or a gear that I’m missing? Grizzly shows one for the G9249 but I’m looking to see if it’s actually my missing gear. Thanks in advance