- Joined

- Aug 20, 2024

- Messages

- 31

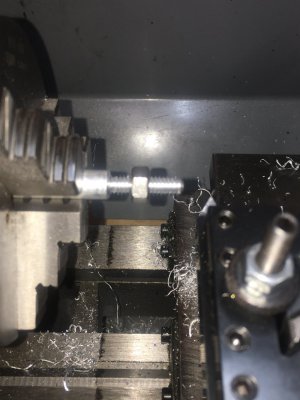

Well everyone…yesterday was a smashing success with the help from all of you and my SIL. We got the 55T and 65T gears 3D printed and trimmed to fit. Despite my inability to find any actual videos of my lathe model wherein the change gears were inserted, I decided to jump into the deep end, dismantle the banjo ad whatever else was in the way. The gears didn’t mesh together at all…about 1/2” out of mesh on the average. Then I noticed the adjustment slots in the brackets…similar to an alternator bracket. I loosened up all the adjustables them kind of worked all the gears in a handful until everything meshed. Note that the large belt pulley had to be removed in order to get the 40T gear in place at position “A”. Nowhere in any manual or video was this explained. I tightened up all the bolts, greased the gears, and rotated the assembly by hand to ensure no issues. Turned on the lathe at 100 rpm, threw the 1/2 nut lever as the indicator came to “1” and…magic! It worked! I’m going to hang my first bolt on the shop wall!

Thanks again!

Thanks again!