I am still confused. That manual states that the lathe has a metric (1.5mm pitch) leadscrew. If that's true (and I have always assumed that all the Vevor lathes had 1.5mm leadscrews) I don't see how

@6Sally5 could have cut an accurate 20 TPI thread using a 40 and 50 change gear combination. 20 TPI is a thread pitch of .050" A 40/50 gear set with a 1.5mm pitch leadscrew will produce a thread with a pitch of 1.2mm or .047"

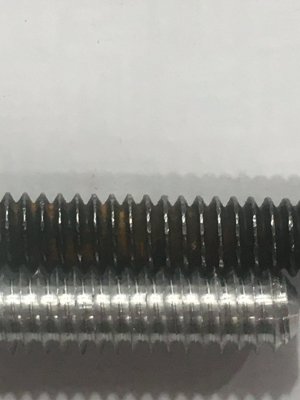

That's a pretty big error (about 6%?). It would be interesting to see a close-up picture of that lathe-cut thread held up to a regular 1/4-20 bolt or threaded rod.

Or, take a piece of 3/8-16 threaded rod and hold it up to the leadscrew to check that pitch?

On a different Vevor lathe, MatthiasWandel found that the threading chart was full of errors, and apparently Vevor hired him to correct the charts.

Matthias said: "After much investigation, I realized the included threading table was very inaccurate, to the point of being practically useless for imperial threads."

So, perhaps the saga continues?