-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 1340GT in the shop

- Thread starter Serpico1985

- Start date

- Joined

- Jan 2, 2018

- Messages

- 586

You might have to align the head-I needed to on my 1340 gt. Not a big deal but a little tedious.Don't panic if it cuts a taper when you make the first cuts.Hey guys,

I finally got my 1340GT single phase I ordered in November. I worked myself up worrying about lifting it on an engine hoist reading about other members difficulty. But it worked out well.

I had to take it off the double pallet it came on and get it lifted high enough that my barrowed engine hoist could fit under the pallet it's bolted to.

As it came out of the box:

View attachment 375001

Set on blocks to allow my engine hoist to get under it:

View attachment 375002

While it was in the garage I cleaned it up and got all/most of the heavy grease off that it ships with. I swapped out the belt for a better one too as that is a universal recommendation. I assembled the stand, installed the leveling feet and rigged the lathe on the hoist:

View attachment 375003

It only took about 5 tries lifting it to get it to stay balanced. It was a little tricky getting the bolt holes to line up but all things considered not very difficult.

Here it is installed:

View attachment 375004

I purchased the PM 4 jaw, PM 5c collet chuck, high precision drill chuck, PM DRO and enough extra oil to do the first oil change after it gets broken in. I previously bought a Dorian BXA QCTP kit.

I barrowed a 15" machinist leveled the bed left to right, then got all the twist out. After getting the twist out I checked the left to right level and it was off only by a very small amount. I won't worry about it until I do the final leveling/test cut procedure.

Quick question. To wire this for power I have a buddy who is a former electrician. The motor for this lathe is 2hp, 11.5 amps. We were planning on using a 20 amp circuit breaker and 10 gauge wire for power. Only other thing that will draw power is the lamp. Does that sound right regarding the wiring and breaker?

Thanks for everyone who helped me figure out what I want and the plethora of info on this lathe that the forum generates.

Zack

- Joined

- Dec 12, 2020

- Messages

- 33

Roger that. I'll keep that in mind.

Thanks again for the info guys.

Next stupid question, pull up a chair.

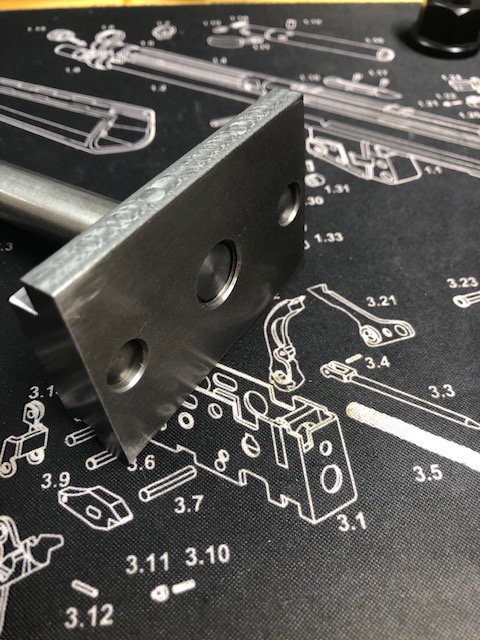

I machined the t-nut for my Dorian BXA tool post kit. I'm a little confused about how the tool post is supposed to attach to the cross feed. The threaded rod is threaded about a half inch and doesn't go all the way into the cross feed threaded hole. What is supposed to keep the tool post from sliding in the t-nut dove tail? Is the rod that came with my Dorian kit not threaded enough or am I missing something?

This is a far as it will go into the t-nut.

I would have thought it should thread into the cross feed:

Thanks.

Thanks again for the info guys.

Next stupid question, pull up a chair.

I machined the t-nut for my Dorian BXA tool post kit. I'm a little confused about how the tool post is supposed to attach to the cross feed. The threaded rod is threaded about a half inch and doesn't go all the way into the cross feed threaded hole. What is supposed to keep the tool post from sliding in the t-nut dove tail? Is the rod that came with my Dorian kit not threaded enough or am I missing something?

This is a far as it will go into the t-nut.

I would have thought it should thread into the cross feed:

Thanks.

- Joined

- Dec 12, 2020

- Messages

- 33

See, even as I typed it out I knew it was a stupid question. Thank you.

- Joined

- Dec 26, 2015

- Messages

- 2,079

See, even as I typed it out I knew it was a stupid question. Thank you.

What is the toolpost T-nut size required for 1340GT?

Definitely a newbie across the board when it comes to machining. Thanks for the advice Bob. Something to watch out for when making your first t-nuts is the height of the nut above the step. There is always some play in a t-slot. When you pull up on a bolt or nut in the t-slot, the top of the...

www.hobby-machinist.com

www.hobby-machinist.com

Note the comment: "Just make sure the “T” leg segment sits slightly below the top surface of the compound when the T-nut is pulled upward - such that the QCTP bottom is pulled down firmly against the top face of the compound."

- Joined

- Jan 6, 2017

- Messages

- 1,214

See, even as I typed it out I knew it was a stupid question. Thank you.

With internet anonymity, the small amount of embarrassment that comes from newbie questions will be insignificant compared the price of replacing parts.

Don't be shy about asking questions. There are are very few buttholes on this site. Most here will happily help out.

You've come to the right place. Of the various forums I frequent, Hobby-machinist, by far, has the most helpful and well mannered membership.