My customer is sending me another tool holder to compare my numbers with as i cut but i dont want to wait until the work gets here and push everything off while waiting on the cutterYour customer should provide you a print or the mating part for fitting. Otherwise you take on risk that should belong to him.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first job!

- Thread starter Brento

- Start date

- Joined

- Jul 20, 2012

- Messages

- 1,238

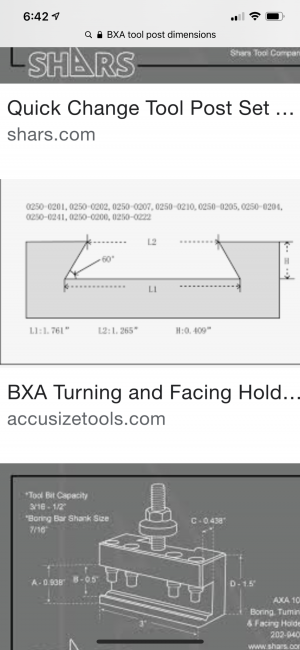

Thank you @Cadillac STS it is a bxa

- Joined

- Jul 20, 2012

- Messages

- 1,238

If you haven’t done a dovetail before definitely practice on a piece of alminium. Less likely to dull your new dovetail cutter you need for steel on the real one.

If he sends you a holder with the bxa in it you could put it next to the part you are going to do and scribe the outline. You would still measure but it would help you see where the cutting goes.

Use a straight end mill and cut that L2 measurement on the drawing all the way down so the dovetail tool only does what it needs to and not cutting out metal it does not need to.

Original poster may know all that but I like to think that these posts will be here for years and searchable so may help someone else down the line.

If he sends you a holder with the bxa in it you could put it next to the part you are going to do and scribe the outline. You would still measure but it would help you see where the cutting goes.

Use a straight end mill and cut that L2 measurement on the drawing all the way down so the dovetail tool only does what it needs to and not cutting out metal it does not need to.

Original poster may know all that but I like to think that these posts will be here for years and searchable so may help someone else down the line.

Last edited:

- Joined

- Oct 11, 2016

- Messages

- 3,866

If you haven't started yet - I have a mittful of Kennametal tool holders. They are around Rc50 hardness, and will eat up your HSS cutter. This job is an advanced job and needs a hefty mill to make a good finish. You have to use a carbide insert dovetail cutter after sawing out most of the metal using a bandsaw.

The expensive way is to ruin HSS tooling to do this. Even a standard carbide end mill will get dulled on this one job. If you have a 1" insertable mill cutter, and a insertable dovetail cutter you can get away with minimal tooling cost.

BTW I have a 1.5" Square Sandvik tool holder I intend to dovetail for my BXA, and I have postponed it for the moment. (I need better tooling before I begin)

The expensive way is to ruin HSS tooling to do this. Even a standard carbide end mill will get dulled on this one job. If you have a 1" insertable mill cutter, and a insertable dovetail cutter you can get away with minimal tooling cost.

BTW I have a 1.5" Square Sandvik tool holder I intend to dovetail for my BXA, and I have postponed it for the moment. (I need better tooling before I begin)

@Cadillac STS you said exactly what i plan to do. Im going to do it in 3 ops prob. I am going to do the L2 dimension first maybe leave a little material to finish. Then i plan to stand it up and take another endmill and wittle some more material out out before i hit the dovetail.

@Dabbler i havent started yet. The job should be here on Tuesday. I have quite a few carbide cutters that i can use for this job. But I appreciate your opinion on the dovetail cutter bc i have been on the fence with getting a fresh set of hss or a carbide insert. And you helped me very much.

@Dabbler i havent started yet. The job should be here on Tuesday. I have quite a few carbide cutters that i can use for this job. But I appreciate your opinion on the dovetail cutter bc i have been on the fence with getting a fresh set of hss or a carbide insert. And you helped me very much.

- Joined

- Mar 26, 2018

- Messages

- 8,408

+1If you have a good bandsaw you might rough it with 3 or 4 cuts.

Sent from my SM-G892A using Tapatalk