-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first job!

- Thread starter Brento

- Start date

As far as i know of i do not have a knife smith around. But i will admit that i was not ready for a hardened tool holder when i first took the job but that goes into my learning curve. Id prob keep my pricing the same but need to get better at an hourly quoting.Let me congratulate you on your first job. Usually a machinist's first job is very enriching, but not in dollars, it is in the knowledge gained on estimating costs for future projects. It teaches you to examine the job more critically, and estimate accurately the difficulty and special tool costs. It also can help in teaching you different approaches at any task.

I would likely look at this job and take a different approach than most of the GOOD ideas here. Step one would be annealing the tool. Then the machining operations (which would be HSS-friendly on annealed steel), followed by a hardening and tempering. This is the same order of operations the manufacturer of that tool used (although they might have skipped the annealing phase, as they likely bought the steel stock already soft). Then the finish would have to be re-worked after all that is done. But then, I started making knives back in the 1970s, so heat treating steel is less daunting for me. Do you have any knife smiths in your area?

- Joined

- Jul 20, 2012

- Messages

- 1,238

Tubal Cain dovetail video: This is part 2 part 1 also helpful

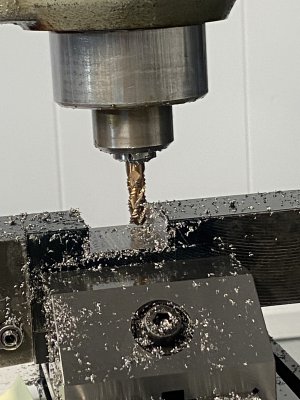

So far it is going good. I feel i am pushing this endmill at a decent rate also. I cant tell my speed/feed really which is why i would like atleast a way to read spindle speed. Believe it or not ive gotten this carbide rougher for 6$ and seems to be holding up very well.

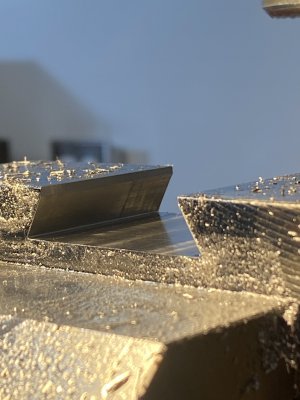

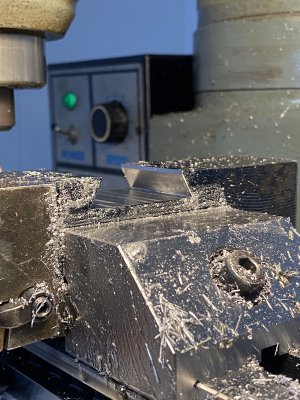

Dovetail is now finished. Just need to drill a hole and tap it for the height adjustment tonight and the job is finished.

Attachments

- Joined

- Jul 31, 2020

- Messages

- 765

Excellent work! I suspect the tap may be a bit of a devil if the material is hard.