- Joined

- Dec 18, 2019

- Messages

- 6,463

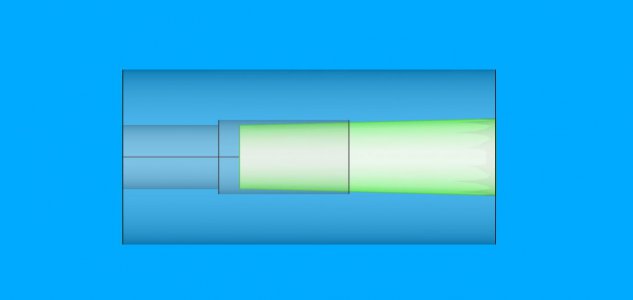

Not sure. Need to measure it. However, if the taper angles match and the taper fully inserts, shouldn't there be a lot of contact? Say one makes a very long taper with a 0.0519" taper per inch and it's 10 inches long, won't the taper engage in the matching section of the spindle? The long taper might be useless, but wouldn't it engage?Just a quick question: Is the spindle taper a short taper? I mean, does it have an MT#4 taper slope, but it is only 2-1/2 to 3" deep? A MT#4 has a small end diameter of 1.02", but your bore is only 25mm (or less than 1"). Your spindle taper has to be at least 4.0625" deep to fully engage a standard MT#4 plug. Time to start "fingering" your baby!