- Joined

- Dec 18, 2019

- Messages

- 6,463

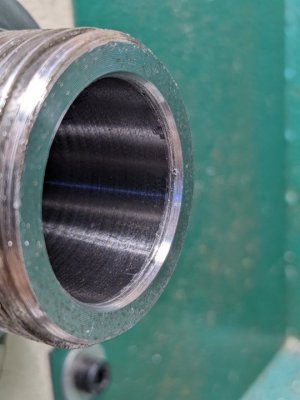

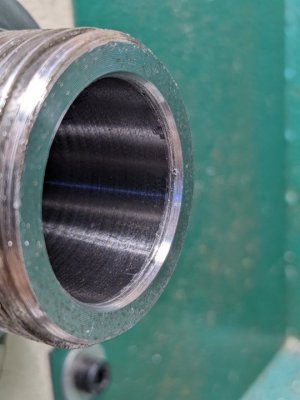

I was using an MT4 to MT2 adapter in the spindle of my G0752Z/G0602 lathe to machine an MT2 soft arbor. It appears the MT4 adapter spun in my spindle. Not only was the adapter gouged, but the very nose of the taper appears to be all roughed up. I'd bet that the taper adapter is wrong, I'll blue it and check. Obviously, I'm more concerned about the spindle. The damage appears to be confined to the very edge of the spindle. What is the best way to clean it up?

Those dark areas in the spindle are rough and sharp. As I said, the damage is at the very edge. Is this just a round stone job to flare it out? Or? Not even sure I want to try inserting the adapter again, even after stoning them, but I guess that's the only way to know if the taper adapter is off spec. Of course the Grizzly could be off spec, but I would think the adapter is the more likely culprit. There is no other evidence of any other contact scarring on the adapter or deeper in the spindle.

Those dark areas in the spindle are rough and sharp. As I said, the damage is at the very edge. Is this just a round stone job to flare it out? Or? Not even sure I want to try inserting the adapter again, even after stoning them, but I guess that's the only way to know if the taper adapter is off spec. Of course the Grizzly could be off spec, but I would think the adapter is the more likely culprit. There is no other evidence of any other contact scarring on the adapter or deeper in the spindle.