What is a Cree LED?

Cree is the industry leader worldwide in high-output LED lamps.

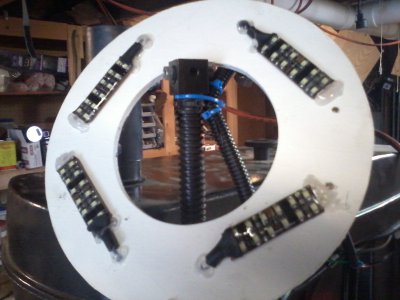

I use their LEDs in my bike lights. They have high power output and good control of color. Most commercially built bike lights (and most flashlights) are made to achieve the highest possible number of lumens. It's a number that buyers can compare and get the most of for the least amount of money, so that tends to drive the market toward blueish lights. However, it turns out the the human eye (at least my human eye) is more comfortable with, and process motion better with light with most of the power concentrated toward the red end of the visible spectrum. Additionally, the things that happen to make up the surface of a bike trail; dirt, rocks, and roots all tend to look the same under blueish light.

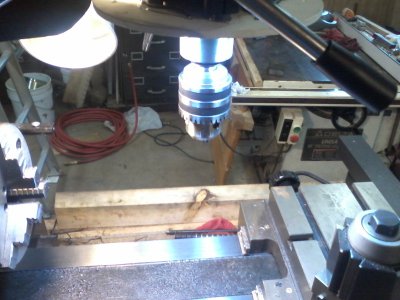

Not sure if any of this applies to machine work, but I don't like blueish LEDs, and Cree (among others) sells lamps in different color temperatures. I buy ones at the neutral to reddish end of the spectrum, under 5000K. It costs more (money and lower lamp output), but the results are worth it to me, YMMV.

http://www.cree.com/lighting

Walt