-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lower priced quick change tooling posts holders

- Thread starter DAN_IN_MN

- Start date

I made one similar to this:

http://swarfer.co.za/lathe/toolpost.php

Cost: $0 (assuming you have some sizable scrap laying about)

There is a similar commercial version made is USA:

http://www.krfcompany.com/krfcatalog.pdf

It is very rigid and provides better visibility than those bulky Aloris type tool posts. I added a lever to the tool block clamp which makes tool changing and positioning a breeze. You can omit the bottom ring if your t-nut is level with the top of the compound.

http://swarfer.co.za/lathe/toolpost.php

Cost: $0 (assuming you have some sizable scrap laying about)

There is a similar commercial version made is USA:

http://www.krfcompany.com/krfcatalog.pdf

It is very rigid and provides better visibility than those bulky Aloris type tool posts. I added a lever to the tool block clamp which makes tool changing and positioning a breeze. You can omit the bottom ring if your t-nut is level with the top of the compound.

- Joined

- Oct 4, 2012

- Messages

- 198

Agree completely " better visibility than those bulky Aloris type tool posts"

Limit your work area...

Charl

Limit your work area...

Charl

I'm sure you could sell it for the same price.

I've made a couple extra holders, but since most of my bits are the same height I find it just as quick to change them. You can mount up to 3 bits in one holder by adding another slot and shortening the clamp screw

Make sure the post is a close fit to minimize tightening.

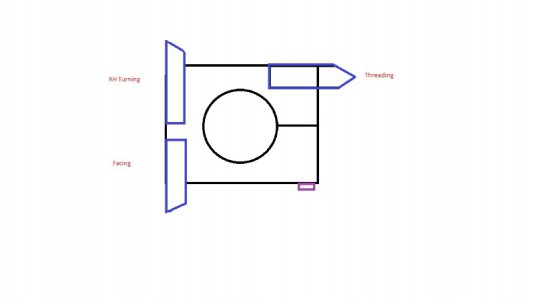

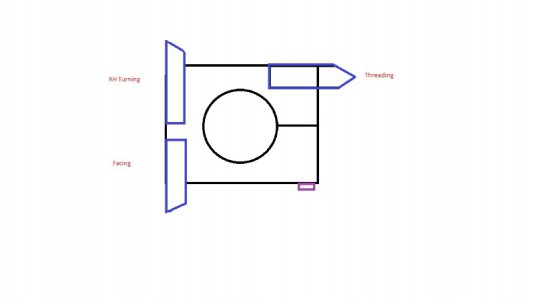

Something like this:

I've made a couple extra holders, but since most of my bits are the same height I find it just as quick to change them. You can mount up to 3 bits in one holder by adding another slot and shortening the clamp screw

Make sure the post is a close fit to minimize tightening.

Something like this:

- Joined

- Aug 7, 2013

- Messages

- 655

I'm sure you could sell it for the same price.

I've made a couple extra holders, but since most of my bits are the same height I find it just as quick to change them. You can mount up to 3 bits in one holder by adding another slot and shortening the clamp screw

Make sure the post is a close fit to minimize tightening.

Something like this:

I'm learning more about the design the more I look at it.

Is the block around 2" sq? What type of steel did you use?

Would it be possible to get a pic of it some what disassembled? Block removed from the post.

Thank you!

- Joined

- Jan 11, 2013

- Messages

- 1,821

The lathe I purchased recently had one of the KRF style posts with it. "1200 Series" boring bar, 1" capacity I believe. Pretty cool system.

- Joined

- Jul 26, 2011

- Messages

- 4,142

If you make tool holders as seen in post #24,I would encourage you to make them of thicker metal. I'm afraid the thin metal above and mostly below the tool (1/8" ???) held in the groove might start to sag down a little from the pressure of the screws and the pressure of cutting also. The top of the groove could also start to bend upwards if not thicker. The illustrations of the KRF tool holders shown in the link are thicker.

Possibly the maker of this cutter holder will reply that he has had no problems. I say wait and see. If the cutter is run into a corner and stressed,I'll bet the tool holder will bend down beneath the lathe tool.

About the KRF illustrations shown: It is ALWAYS BETTER to have an angled tool presented to the metal so that if it swings under the pressure of cutting,it swings AWAY from the metal,rather than swinging INTO it. The KRF cutters shown would swing INTO the metal if they slipped,ruining the job and possibly springing the bar being cut into a curve,causing a crash and ruining your chuck from the strain on the jaws. I don't know why they designed them that way. If you have read "how to run a lathe" or the Atlas lathe manual,they mention this placement of lathe tools to swing away from the metal,not into it. Best to play it safe for the sake of your chuck and machine.

Possibly the maker of this cutter holder will reply that he has had no problems. I say wait and see. If the cutter is run into a corner and stressed,I'll bet the tool holder will bend down beneath the lathe tool.

About the KRF illustrations shown: It is ALWAYS BETTER to have an angled tool presented to the metal so that if it swings under the pressure of cutting,it swings AWAY from the metal,rather than swinging INTO it. The KRF cutters shown would swing INTO the metal if they slipped,ruining the job and possibly springing the bar being cut into a curve,causing a crash and ruining your chuck from the strain on the jaws. I don't know why they designed them that way. If you have read "how to run a lathe" or the Atlas lathe manual,they mention this placement of lathe tools to swing away from the metal,not into it. Best to play it safe for the sake of your chuck and machine.

- Joined

- Nov 16, 2012

- Messages

- 5,596

I'm glad you said this George, as I was thinking the same thing. With all due respect to the one who made it, I see that it has small bolts to change elevation. I have my doubts about the stability of that and feel the whole thing will cock sideways under pressure as well as ding-up the surface of your compound seating area. -Maybe I'm wrong and will stand corrected if so. At a quick glance, it does not seem rigid enough except for light cuts on moderate/mild material.

AXA QCTPs are pretty affordable -and are basically bulletproof. There are various designes of tangential holders that are intriquiging and would like to try one some day.

Ray

AXA QCTPs are pretty affordable -and are basically bulletproof. There are various designes of tangential holders that are intriquiging and would like to try one some day.

Ray

If you make tool holders as seen in post #24,I would encourage you to make them of thicker metal. I'm afraid the thin metal above and mostly below the tool (1/8" ???) held in the groove might start to sag down a little from the pressure of the screws and the pressure of cutting also. The top of the groove could also start to bend upwards if not thicker.

About the KRF illustrations shown: It is ALWAYS BETTER to have an angled tool presented to the metal so that if it swings under the pressure of cutting,it swings AWAY from the metal,rather than swinging INTO it. The KRF cutters shown would swing INTO the metal if they slipped,ruining the job and possibly springing the bar being cut into a curve,causing a crash and ruining your chuck from the strain on the jaws. I don't know why they designed them that way. If you have read "how to run a lathe" or the Atlas lathe manual,they mention this placement of lathe tools to swing away from the metal,not into it. Best to play it safe for the sake of your chuck and machine.