- Joined

- Dec 18, 2019

- Messages

- 6,447

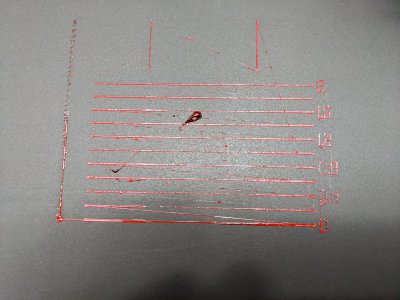

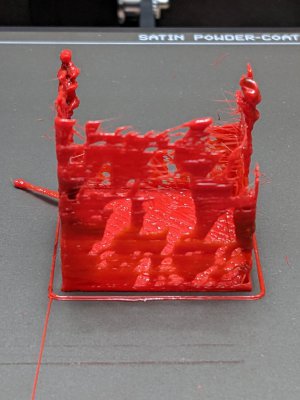

Recompiling Prusa's Marlin isn't that bad in linux. git clone the repository, and check if I have the right flavor of awk, and run the script. Since I have built FreeCAD from source, I can't imagine doing Marlin would be bad at all. Anyways, generated the g-code and am starting the kfactor run.Follow the directions in that link. You have to run their test print to figure out what those K numbers are. Then you can add them to your slicer's starting Gcode as shown instead of recompiling Marlin, which is a nuisance to be sure. You can't just enable it as without numbers specific to your printer, it's just going to make things worse.