- Joined

- Dec 18, 2019

- Messages

- 6,447

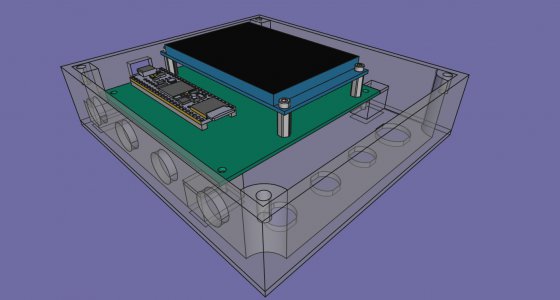

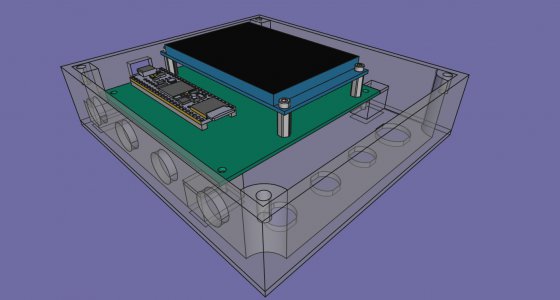

So I thought I would try PETG. I'd like to print this box eventually. I made a couple of prototype prints in PLA and they came out rather well.

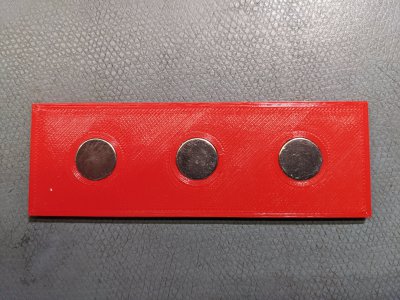

So I changed my steel plate to satin and sort of adjusted the Z so it wasn't too high. I did notice that I will eventually need to address leveling the whole bed, but that is not the main issue. Then I printed a test file just for figuring out the magnet in a pocket thing. It came out ok. I printed it horizontally like this.

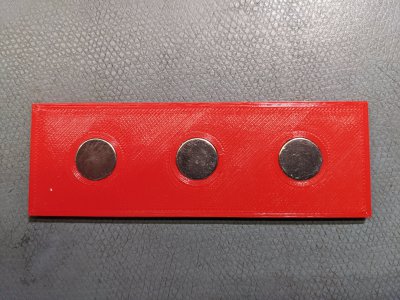

If you look carefully at the back side, (the first picture) you can see a faint rectangle. That's because some dope, not saying who, forgot to clean off the test pattern before printing this. Guess it is ok, but I'm soliciting advice. Then I thought, that's nice but what I really want to know is how it will print if the piece is standing on the long narrow edge, like it would be in the box. So I moved the piece on it's long narrow edge and sliced it with supports everywhere. And printed it at 0.2mm quality. After I peeled off the supports this is what I have.

Not so pretty. Actually kind of ugly. Nowhere as nicely printed as the PLA. Lots of little nubs, banding across where the pockets are and some overhanging at around 29mm in Z. Is this as good as it gets? If not, what can I do to improve the vertical wall quality? I exported my config.ini and changed the extension to .txt to get the forum to accept the upload.

Thanks for any and all observations.

So I changed my steel plate to satin and sort of adjusted the Z so it wasn't too high. I did notice that I will eventually need to address leveling the whole bed, but that is not the main issue. Then I printed a test file just for figuring out the magnet in a pocket thing. It came out ok. I printed it horizontally like this.

If you look carefully at the back side, (the first picture) you can see a faint rectangle. That's because some dope, not saying who, forgot to clean off the test pattern before printing this. Guess it is ok, but I'm soliciting advice. Then I thought, that's nice but what I really want to know is how it will print if the piece is standing on the long narrow edge, like it would be in the box. So I moved the piece on it's long narrow edge and sliced it with supports everywhere. And printed it at 0.2mm quality. After I peeled off the supports this is what I have.

Not so pretty. Actually kind of ugly. Nowhere as nicely printed as the PLA. Lots of little nubs, banding across where the pockets are and some overhanging at around 29mm in Z. Is this as good as it gets? If not, what can I do to improve the vertical wall quality? I exported my config.ini and changed the extension to .txt to get the forum to accept the upload.

Thanks for any and all observations.