- Joined

- Dec 18, 2019

- Messages

- 6,447

Loosened the X belt a little. Y looked ok. Changed the fan settings. I'll give it another go. At least this is a test piece, the real box is an 8 hour print. I can flub up a few test prints and not mind it.

Thanks. I found that link. As a beginner I read that kind of material and then get sort of paralyzed when I look and see hundreds of parameters to fiddle with and realize only a couple of them might fix anything. And I don't know which parameters they might be. The worst part is when they refer to a particular parameter and you find nothing by that exact name. I'll eventually figure it out, but I'd imagine millions of hours have been wasted by beginners like myself trying to muddle their way through similar issues.This page is usually my first stop to help diagnose printing problems:

https://www.simplify3d.com/support/print-quality-troubleshooting/

click on an issue and you get more detailed info.

Here's the page for "Blobs and Zits":

https://www.simplify3d.com/support/print-quality-troubleshooting/blobs-and-zits/

Brian

EDIT: also, that "ghosting" might be oscillations/ringing. The machine may have some vibrations due to some fast heads moves around the pockets.

You might try slowing down the print.

https://www.simplify3d.com/support/print-quality-troubleshooting/vibrations-and-ringing/

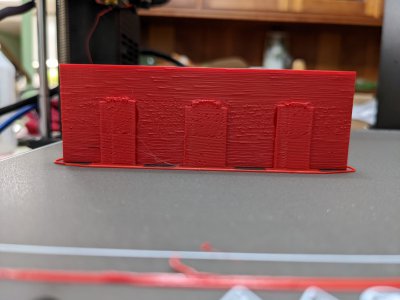

In my limited experience, that makes it look like your flow rates aren’t calibrated.Didn't help that much. There was some improvement, the line at Z=29mm is gone, but there are a lot of nurbs, or nubbins. You can see some sort of dark contaminant in the filament. Looks almost like swarf. Strange, this is Prusament PETG ordered direct from Prusa.

View attachment 427393

Should be ready to remove from the plate now. So far, this is not a good surface finish. Hope when I pull the supports the inside of the pockets look better than before.

I see a section in Filament Overrides called retraction. Man, just finding that took a bit.fiddling with the retraction settings can often help with that.

Is there anywhere where the fine points are written up? Like how to systematically converge on good settings? Hunting and pecking randomly doesn't seem efficient. From the perspective of a newbie I am hearing I need 100's of hours effing around, primarily since I know NOTHING about this stuff. I would have thought, naively, that using Prusa filament on a Prusa printer using default settings would get me in the ball park. Indeed, they aren't bad for the test piece laying flat. But for a short section of box wall, the settings are no good.Pretty much everyone has really good points. Tuning is the first thing you should do with any new filament. I'll add that PETG likes a little more height off the bed so that it's laid down more than squished like you would do the PLA. Also, if you have a Bowden style extruder, the retract amount will be way higher than if the extruder is direct drive. I found a recommendation to use a retract speed of 25 which actually works really well for me, but another thing that will prevent stringing is the travel speed (not the print speed). Moving to a new location quickly will snap the string instead of drawing it out. Also, too much fan will make it shrink and pull up at the corners, or even separate the layers. Too much heat can do the same thing, or to low a bed heat. So many things to consider.