- Joined

- Oct 14, 2013

- Messages

- 984

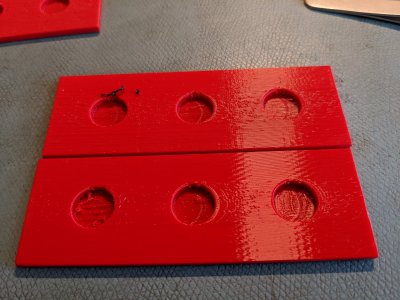

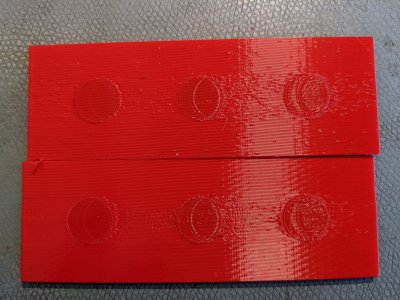

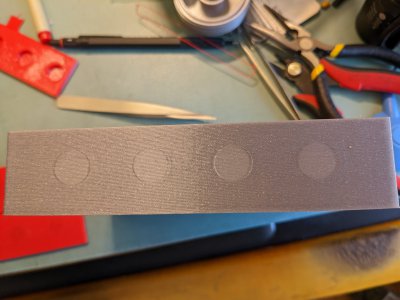

I would go back to having the outside surface down and pockets up. Standing up is just asking for problems...

I always try to maximize bed contact and have the bed as a finish surface.

Sent from my SM-G715A using Tapatalk

I always try to maximize bed contact and have the bed as a finish surface.

Sent from my SM-G715A using Tapatalk