- Joined

- Apr 16, 2014

- Messages

- 142

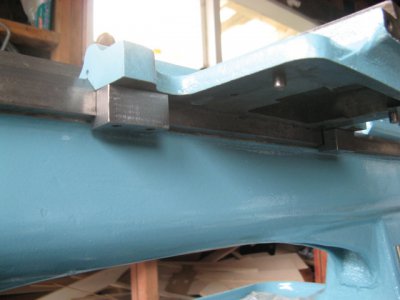

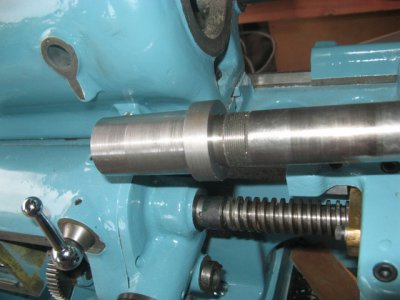

Have started to reassemble the lathe. I need to make the apron clamps to continue. They don't seem to work like jibs, they seem to be sliding fit. So i measured it up as best I could and started machining. Results so far are promising and I will fit each one as I go. Starting to get a feel for how she will look with the tailstock on (but not fitted), the chrome will be pretty bingy. Drive belt could be months away so I am going with plan B which is splicing. Any tips welcome.