- Joined

- Apr 16, 2014

- Messages

- 142

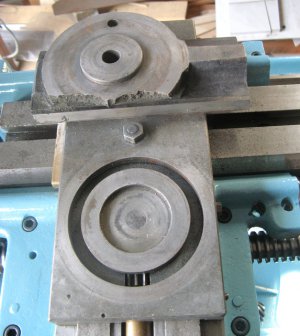

Got the spindle in and the gear on the back of it. That meant I could mount the back gear housing. I am keen to get the servo running about now, so I can start on the motor mount. I have some ideas for duplicating the original control system and also a rpm gauge. This is where the 3D printer will be useful.