- Joined

- Dec 28, 2022

- Messages

- 253

Let’s hope so! I’ll be giving it a go in a couple of hours.All he needs is 12mm of movement. I believe just loosening up the bearing block might be enough to get the saddle off.

Let’s hope so! I’ll be giving it a go in a couple of hours.All he needs is 12mm of movement. I believe just loosening up the bearing block might be enough to get the saddle off.

Is that what that is? Cripes. As you can tell, I have never needed a carriage lock yet, but now I know!just like the carriage lock does on yours.

The two smooth rods can be slid through, but the lead screw couldn't on the 2 smaller lathes (even with the half nut completely open)you could slide the whole assembly off the end?

I was assuming the QCGB was staying on, and the rods were to be removed by disconnecting them.All 3 are connected at that end with a taper pin or a set screw

On 2 of my lathes they were installed the way they are on @jareese lathe. My LeBlond, the heads are on the top of the saddle, and thus easily accessible. They had better be on the LeBlond. The saddle is 160 lbs and the Apron is another 110lbs.Bummer they installed the hold-down bolts upside down

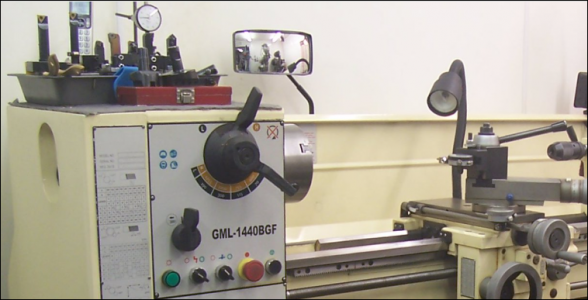

@Charles scozzari - is the mirror so your wife doesn't sneak up on you?Just want to put this out there, It's possible that the bed is generic to other branded name machines of that size which in turn would mean the carriage from another lathe will fit IF Eisen can't help you which for the life of me I can't understand that is even possible. My 1440s bed is 7 5/16" wide and your carriage looks the same as mine I only mention this because it seems the vast majority of these lathes come from the same plant. If it were mine I would try to avoid welding if only as a last resort. Just saying............It will take some time, but you will get it done.View attachment 441491

Maybe he is taking a cue from "Anchorman"; "Hey everybody, come here and see how good I look!"