- Joined

- Aug 13, 2024

- Messages

- 11

Newbie to this forum! I entered my intro yesterday on the meet n greet section. You can see more of my current project there. It's nice to be so warmly welcomed so quickly by some fair-feathered friends!

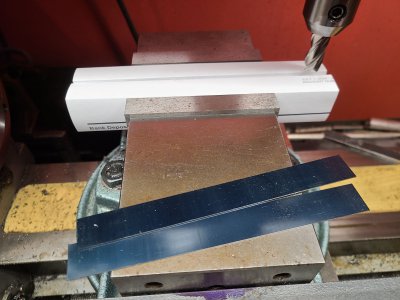

I'm trying to use my inherited Smithy vertical milling machine to do some work on two pieces of mild steel, rough dimensions of 1/4T X 3/4 X 15.

The supplied vise jaws are only about 4.5 in width, shy of supporting my half-length by about 3".

Why can't I buy some rectangular steel bar stock and cut two lengths, as illustrated by the paper pieces shown in the pic, to add the necessary length support? The end-result finish surface is not absolutely critical, but working with this longer vise jaw length would seem like a possible solution, although I will STILL have to turn my stock around and only work half the overall 15" length at a time.

Otherwise, if I'm absolutely limited to sticking to the 4" vise capacity, I've got to duplicate the milling 4 times along the length of the 15" piece.

Whadaya guys think?

I'm trying to use my inherited Smithy vertical milling machine to do some work on two pieces of mild steel, rough dimensions of 1/4T X 3/4 X 15.

The supplied vise jaws are only about 4.5 in width, shy of supporting my half-length by about 3".

Why can't I buy some rectangular steel bar stock and cut two lengths, as illustrated by the paper pieces shown in the pic, to add the necessary length support? The end-result finish surface is not absolutely critical, but working with this longer vise jaw length would seem like a possible solution, although I will STILL have to turn my stock around and only work half the overall 15" length at a time.

Otherwise, if I'm absolutely limited to sticking to the 4" vise capacity, I've got to duplicate the milling 4 times along the length of the 15" piece.

Whadaya guys think?

Attachments

Last edited: