- Joined

- Aug 2, 2020

- Messages

- 691

I have been watching for tooling to fit my old Midway Millmaster mill which uses B&S 9 collets.

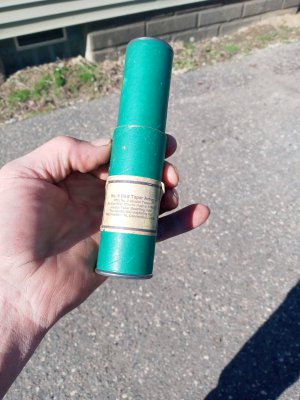

Found this NOS B&S9 to JT 3 adapter online and bought it. I have a spare drill chuck with JT3 and want to use them as a pair.

It arrived today and it seems fit my spindle and it does fit the chuck but it has a tang on it instead of a tapped hole for the drawbar.

Now what?

Can I use it as is or do I need to cut the tang off of it and drill and tap a hole for the drawbar?

Am new to all this so bear with me.

Thanks

Found this NOS B&S9 to JT 3 adapter online and bought it. I have a spare drill chuck with JT3 and want to use them as a pair.

It arrived today and it seems fit my spindle and it does fit the chuck but it has a tang on it instead of a tapped hole for the drawbar.

Now what?

Can I use it as is or do I need to cut the tang off of it and drill and tap a hole for the drawbar?

Am new to all this so bear with me.

Thanks