thanks Rick. 1st, see my response before this. the boss on the chuck isn't even in play as the hole in the L1 plate is bigger than the boss. 2nd, this isn't my idea, I stole it from a guy on YouTube. see link in my other response.I think I wasn't getting what you want to do. Are you proposing to use the threaded boss (A/B) on the backside of the 5C collet chuck as the insert that goes into the recess (C/D) formed by the backplate and front side of the L1 taper? If so, what are the dimensions of the several lettered locations indicated. Also, what are the unfilled screw holes on the back side of the chuck (ellipse)? What is the bolt circle diameter of those unfilled holes, in relation to dimension "C"? Will these open holes be used to secure the chuck to the backplate? If so, is there room on the backside of the backing plate for those mounting bolts with clearance from the OD over the L1 taper (F)?

If I'm understanding correctly and things all fit, your thought of drilling/tapping screw holes in the backplate for adjustment screws that work against the boss on the back of the collet chuck just might work. Whether you have to turn down that boss to fit within the backplate recess or not, the runout of the OD of that boss may not matter, because 1) there needs to be substantial clearance for there to be an adjustment ability/range, and 2) the adjustment screws will push the chuck around while you indicate the chuck OD, 5C taper or stock held in the collet (my preference).

Rick

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mounting a 5" Bison 5C collet chuck on an L1 backing plate.

- Thread starter yota

- Start date

- Joined

- Dec 10, 2023

- Messages

- 131

My bad, I suppose. Hadn't viewed the video. Makes a lot more sense now and my comments are not relevant. I had the sense that the sizes were quite different, at least.thanks Rick. 1st, see my response before this. the boss on the chuck isn't even in play as the hole in the L1 plate is bigger than the boss. 2nd, this isn't my idea, I stole it from a guy on YouTube. see link in my other response.

I posted the video after you made your comments so you would not have seen it. BTW, the 3 unused threaded holes on the back of the bison chuck I believe are for jacking screws to separate the 2 halves. will find out when I disassemble it. you took quite a bit of your time marking up my photos for your response and I appreciate that.My bad, I suppose. Hadn't viewed the video. Makes a lot more sense now and my comments are not relevant. I had the sense that the sizes were quite different, at least.

I had a junk chinese one before this and sold it to buy this Bison. it's def not junk.It is all doable , but most of the import 5c chucks are junk. You are better off with a draw bar and an adapter to 5c

well, this idea isn't going to work with my L1Spindle. the plan was to recess the chuck in the back plate and drill 6 bolt holes thru the flange of the backplate to bolt it to the collet chuck. not having a brain, I didn't figure out until I had the back plate in hand that the bolt holes would go into the big L1 taper behind the flange and not into the flange. that is one huge taper.

- Joined

- Dec 10, 2023

- Messages

- 131

This is why I was asking the questions, with the photos marked up with lines, letters and an ellipse....snip... bolt holes would go into the big L1 taper behind the flange and not into the flange. that is one huge taper... snip...

Might be kind of kludgy, but what about adding an intermediate plate, to which you would bolt the collet chuck, but with an OD large enough to place mounting bolts through the backplate flange? Might not be so kludgy, but would add 1/2" or so the the overall length, but...

If I were faced with this prospect, I think I'd be truing to use the three unused bolt holes, shown in your photo in post #4 and in my marked up photos, where the ellipse is.

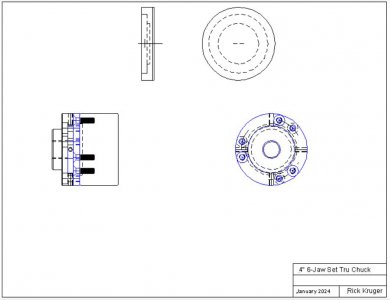

And... if I were going to do that, I would likely put those "Set-Tru" adjusting screws in that intermediate plate to work off of the collet chuck threaded spindle boss to add adjustability to the overall assembly. I have a Bison 5", 5C, Set-Tru collet chuck and love the adjustability. Looks just like yours, but with the adjustment screws.

There is an article in Machinists Workshop that is also featured in "Projects in Metal" One that details making such a backplate for an ordinary 3-jaw scroll chuck. I did this in 2001 using a 4", 3-jaw on a minilathe. I've recently acquired a Craftsman 6" lathe for which I got an LMS 4", 6-jaw chuck that I plan on making a similar "adjustable" backplate for.

"Projects in Metals; Aug 1988; Greater Precision for Scroll Chuck;; Richard Torgerson;; Adding adjustment screws to lathe chuck back plates"

Attachments

was thinking about this earlier. I have a 6" back plate from my old SB9A. just thought adding another layer would make getting concentric even worse, but nothing to really lose at this point but a backing plate. as I'm retired my time is free and every cut is a learning experience for me.

I was interested in this esp as I could cut the 1st back plate to the lathe with its L1 taper and thread. the intermediate plate has the same 1-1/2 x 8 TPI threaded hole as the Bison chuck.

wow, had to correct a bunch of typos.

I was interested in this esp as I could cut the 1st back plate to the lathe with its L1 taper and thread. the intermediate plate has the same 1-1/2 x 8 TPI threaded hole as the Bison chuck.

wow, had to correct a bunch of typos.

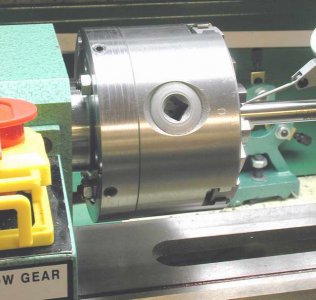

went forward with the intermediate mounting plate as the chuck bolts are in too small of a bolt circle for the big L1 backing plate. so, the L1 plate is 8" diameter, the intermediate plate is 5-11/16 dia and the chuck is 5" diameter. kind of a mish mash. I recessed the intermediate plate into the L1 back plate 0.4195" to center it and so I could drill the edge of the L1 plate in 4 places for some set tru pins with set screws. it is fastened to the L1 plate with 4 1/4-20 bolts. I'm going to recess the Bison collet chuck into the intermediate plate in order to center it also but only 3/16 to 1/4", haven't made up my mind yet. the 6 bolts that hold the 2 haves of the chuck together will be replaced with longer ones which will go thru the intermediate plate and into the chuck as the final fastening. question:

where would you drill thru the edge of the L1 back plate for the set tru pins, right opposite the 4 mounting bolts or in between the mounting bolts? see photos. the open holes in the intermediate plate are from it's previous life.

where would you drill thru the edge of the L1 back plate for the set tru pins, right opposite the 4 mounting bolts or in between the mounting bolts? see photos. the open holes in the intermediate plate are from it's previous life.