- Joined

- Aug 6, 2015

- Messages

- 4,292

There is so adjustability. Worst case scenario, you can install a new lead screw and nut…Hi all my Heros

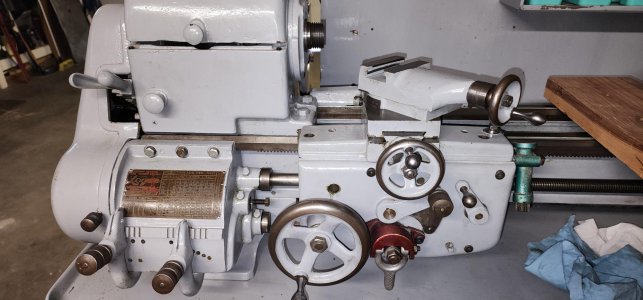

I have limited experience with a lathe so bear with me please. A friend gave me a Logan 820 from 1947. It has been siting for ~20 years. Dirty but no rust. I am cleaning it up and learning how it is built. It has some minor issues. A few loose screws, missing screws, very small dings on the bed. What worries me most is the play in the Compound hand wheel and the same in the Saddle. Both are about .045". Is that normal? If not what is normal. Everything moves smoothly. No broken anything that I have found yet. Every thing seems to work as near as I can tell.

I have both a 3 jaw and 4 jaw chuck I need to clean up too. It came with KDK tool post and 3 tool holders and several HS tools of various geometries.

I purchased the manual online. The cost was $25.00 for the manual and $23.11 for shipping. WOW that is a lot for mailing a book.

How important is it to precision level this machine?

Any information would be appreciated. Pleases steer me in the right direction.

Does it have the same play along all the travel? Or just in a section? That is one way to know if it is adjustment or needs replacement of parts.

And congratulations!!! I have the same model and just love looking at it!!