- Joined

- Sep 2, 2013

- Messages

- 5,438

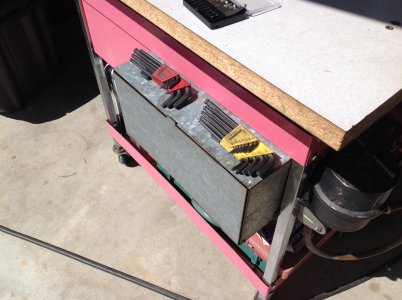

Have been back home in CO now for two weeks. Had tickets to leave PR on April 7th, but decided to get back home while we still could. Have been doing honey do's, and vehicle repairs, but last week I found time to finish my Franken-vac project. Picked it up at a moving sale for $20. Its all stainless steel and cast aluminum construction, with a heavy duty motor, and a lot of sound insulation. When I went to check it out I found the on/off switch toggle was broken off. Replaced the switch and added a standoff to prevent breaking the new one when setting it upside down on the floor. On first start up the motor made a loud screaming sound. Pulled it apart, removed, disassembled, cleaned, lubed, and reassembled the upper and lower ball bearings, cleaned up the commutator, and reassembled the motor. Cleaned, and straightened up the three stage aluminum impellers.

The vac was originally a wet only unit, no filter just a float mechanism inside. I ordered two large filters, and made up some mounting plates and hardware. Used the plastic caps that came with the filters to join them together. It didn't come with a hose, so I modified it to accept an extra shop vac hose and accessory's I had on hand. Works better than any of the large plastic ones I've had in the past, and is much quieter. All in all, a fun little project. Cheers, Mike

The vac was originally a wet only unit, no filter just a float mechanism inside. I ordered two large filters, and made up some mounting plates and hardware. Used the plastic caps that came with the filters to join them together. It didn't come with a hose, so I modified it to accept an extra shop vac hose and accessory's I had on hand. Works better than any of the large plastic ones I've had in the past, and is much quieter. All in all, a fun little project. Cheers, Mike