- Joined

- Feb 1, 2015

- Messages

- 10,082

I did something similar on my Tormach 770. The 770 has the head fixed to the vertical carriage and is pinned at the factory using two tapered dowel pins, one at the lower left and the other at the upper right. My machine was slightly out of tram. I checked the vertical ways and corrected the slight misalignment. Fortunately, the head was close enough in the y direction to not require shimming but the the head needed to rotate to correct the tram in the x direction.

I pulled the lower left tapered pin and loosened the bolts holding the head to the vertical carriage, thus permitting a slight amount of rotation limited by the clearance holes for the bolts. In order to permit rotation in a controlled and precise manner, I needed a mechanism similar to your concept. I elected to do this in the vertical direction. A Tee shaped block was mounted on the head and straddled by a pi shaped block mounted on the carriage. Two 3/16"dowel pins and a single bolt were used to fix the Tee block. The pi block was fixed with two countersunk socket head cap screws. The legs of the pi block were tapped for 3/8"-24 bolts which are used to make the adjustment. Once the head was trammed correctly, the bolts were tightened and the lower left tapered pin was inserted to firm contact.

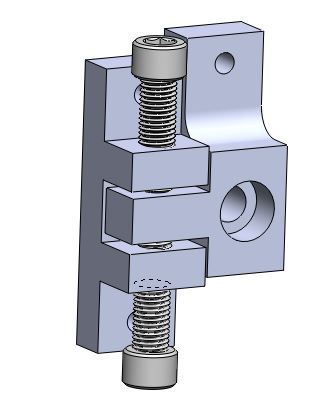

Tis is the original model. In production it was modified to add a second leg on the bottom of the Tee block.

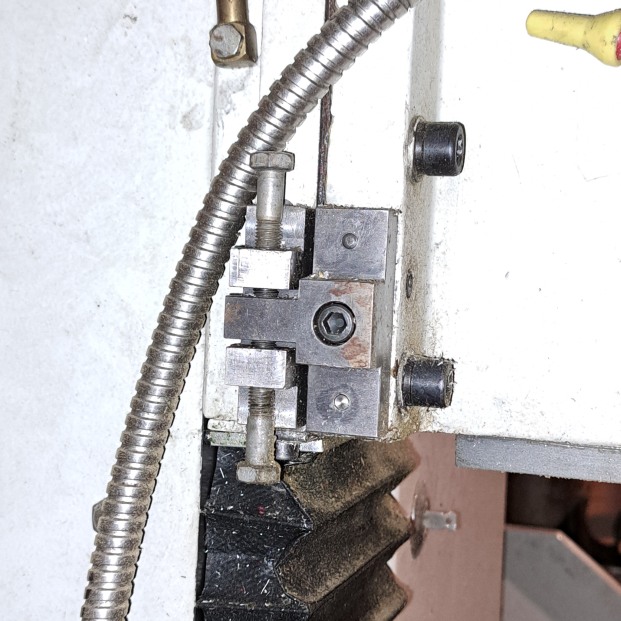

Here it is mounted on the mill.

I pulled the lower left tapered pin and loosened the bolts holding the head to the vertical carriage, thus permitting a slight amount of rotation limited by the clearance holes for the bolts. In order to permit rotation in a controlled and precise manner, I needed a mechanism similar to your concept. I elected to do this in the vertical direction. A Tee shaped block was mounted on the head and straddled by a pi shaped block mounted on the carriage. Two 3/16"dowel pins and a single bolt were used to fix the Tee block. The pi block was fixed with two countersunk socket head cap screws. The legs of the pi block were tapped for 3/8"-24 bolts which are used to make the adjustment. Once the head was trammed correctly, the bolts were tightened and the lower left tapered pin was inserted to firm contact.

Tis is the original model. In production it was modified to add a second leg on the bottom of the Tee block.

Here it is mounted on the mill.