Hi

@Scott-ak

Wow! Read the whole thread! Thanks for your comment, I am looking to learn more as I am still pretty much a newbie at machining. I am glad you are happy and satisfied with your 1440GT. Am I to assume that it is the PM version? I have a CNC mill. Don't think I want a CNC lathe yet. CNC commonly gets in the way of getting the job done.... However, I can see that an electronic lead screw would make my 1440GT much easier to use.

Yes they are simple, in concept, but on my machine... not easy to move nor easy to move to the correct position. Maybe after I have broken the machine in for a few years the edges of the gears will be worn off so that they slide together more easily. Maybe the edges of the gear teeth are still to sharp/precisely cut. Also, sometimes just getting either thread gear handle to move is difficult. Seems I spend a lot of time turning the spindle (by hand or via jog) to get the gears to align so that the levers will move. Then there are the couple of positions where the P-Q-R-I-Twill not drop in. I.e. nothing is engaged even though the lever is aligned with the letter. I have even started threading only to have the lever slip a bit and the gear drop out. The saddle just stops moving. Likewise for the A-D knob. Sometimes it just does not want to engage. Getting it to disengage does not seem to be as much of an issue. Yes, I am familiar with getting the gears to align, just difficult so far. As far as dropping out once engaged I think this is just a poor design. I suspect that there are small detent stops and springs with ball bearings that are suppose to fit into the detent (small depressions) to ensure that the lever is properly located. I found these in the speed levers, H-M-L, when I had the knobs off while making a new front panel. I posted a picture of these detent stops in my VFD conversion posting. If you want to see a picture of them then: See photo 14a at post #4 of

https://www.hobby-machinist.com/thr...tronic-components-pm1440gt-vfd-3-phase.95058/ . Anyway this detent method is just not a good way to lock the lever positions. They should be spring loaded pins that drop in to place like what is done in the PM1340 threading levers or in my old SouthBend 10.

The middle position, M, is poor at best and sometime the gear does not engage, but more importantly, once running I find it sometimes jumps out of position and the spindle stops turning or grinds the gears. Once, again changing these positions is still difficult. Maybe with gear edge wear (break in) it will be easier. I am not the only one who has observed this jumping out of gear and it maybe partly due to the motor not running smoothly at a constant RPM. In all fairness to the lathe and motor, the motor is not designed to run at non-60Hz frequencies. But doing so is a good portion of why I went to all of the trouble to do a VFD conversion... to be able run at lower frequencies. I also purchased 3 phase because the motors are suppose to run more smoothly than single phase. (I may run some tests where I try to measure the motor frequency stability at both 60 Hz and at lower frequencies like 20 or 25. The motor does work at even lower frequencies as I use the 6Hz for jogging the spindle.) However, a 3HP motor designed for variable speed is not cheap. Some folks have changed this motor, but not to a true variable speed design. The worst example I have seen of this unstable motor running at variable speeds in in a you tube video. Here it is shown that the speed lever will jump out, and back into, the M position while accelerating up to speed. It is awful.

. I did not have nearly this much of a problem and thought I had it fixed by changing the VFD acceleration profile. So I posted that result on YouTube:

. The fellow replaced his motor with a Marathon E470 motor. But I do not think that this is a true variable speed motor. Still expensive.

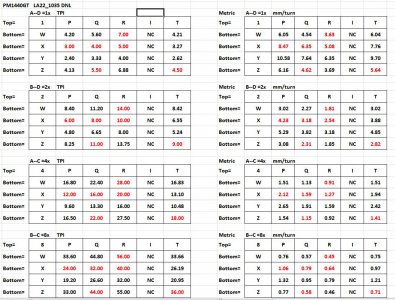

So, my reference to changing gears is largely due to my having a Southbend Heavy 10 for the last 20 years. I purchased it use from a machine shop. I think it was built in the 1970s. This machine has the drop in pin style of gear box and works very well. Only a minimum amount of hand spindle turning is all that is ever needed to get engagement. These gears never drop out as the pins are secure. Wonderful old machine. The threading gear box has 10 main gear settings for each of the 7 factors of 2x gear settings to yield 70 possible TPI values. I suspect that you have seen it, I will post an attachment photo of the SB TPI pin levers gear box. Anyway one only has to move ONE lever to achieve 10 thread changes. (It was a disappointment that my modern machine offers so few, 6 an only if you move two levers.... see the red entries of the table I posted above, post #37)

Anyway, I thin the PM1440GT is over all a very nice machine and I am looking forward to using it for a long time. One thing I may do at some point is to rebuild the SouthBend cross slide parts so that I can make decent threads......and parts of the tail stock. But there are a lot of other projects in the que first. Most of the rest of it seems to be pretty good.

Dave.