I have have the PM1440GT, but have not been using it long enough to form a strong opinion. It seems like a very nice lathe. I did not even consider the larger TL lathe as it too big to get into/ fit into basement room and was considerably more $. I am pretty sure that both of them are made in Taiwan so should be high quality. It is not mentioned on the front page of the web side, but I think it is in the description.

Most importantly, if you have any questions about the two machines just contact Matt, the owner, of PM. (or I will try to provide info about the GT but I am only a hobby machinist so..... ) He is very helpful and always responds. However, he does travel at times and so a response may take a day or longer. Also, he has "support" folks who are pretty knowledgeable. Just give them a call. Also, if I read your location correctly, you are not that far away. probably less than a two hour drive from PM. PM is located out by the Pgh airport so you do not have to come all the way to the city. If they have them in stock you could just visit them and see the machines. I live in Pittsburgh so they are close for me and I have been to the PM site a few times. They are well set up, a nice facility, and have lots of inventory of parts and machines and Matt has been in this business for several years, ~15-20, so clearly is an ongoing concern. I am pretty sure that he was a machinist before starting this business. There have been folks on this site who drive there from farther distances than you have to pick up their machines.

The GT has a gear box for threading English treads. You can read the threads that can be cut with the standard gears on the front tables of the lathe. However, there are a lot of other thread ratios that can be gotten at with the gear box. I just have not had time to fully explore this. It requires gear changes to go to metric and 13 tpi as you mentioned and comes with a number of metric conversion gears. Changing the gearing is pretty much standard process. I also have an old South Bend 10 heavy which I have used for a few years. That old machine has a wonderful gear box that only requires two levers! The SB10 also requires gear changes to get to metric but I never got around to finding a set. But you should call and find out about delivery time as the supply chain problems may have depleted his inventory of either model.

You did not post a picture of the front of the 1440GT. I do not think there is a good picture on the site or in the manual of the front of the head stock so that you can see the tables and the levers. However I have posted on where I describe my recent 3ph VFD conversion posting.

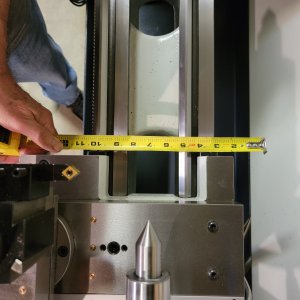

In this posting there are two descriptive documents, Part 1 and Part 2, attachments. Part 1 is about the PM1440GT and its electronics as it arrives (Almost, I put it on casters on it at PM before it left PM to come to my location). Anyway, inside the attachment "PM 1440GT Part 1 FacOriglElecDescript DNL L910_1440.pdf" you will find Photo 3 which show the cover listing of threading and feed rate tables as well as the two gear shift levers P, Q, R, ... and W, X, Y, .. and knobs A-B and C-D. I think the two knobs are just factors of 2x each, i.e. 1x, 2x, 4, and 8x. These two knobs, as well as the upper left-right knob can be rotated to the vertical (up or down) position, but I think this disengages the drive. The two levers set the basic threads. The photo was posted as a high resolution image so you should be able to expand it to see the print very clearly. (If HM lowers the resolution just let me know and I will post an original or send you one such). (In the photo I had not removed the plastic protective cover yet and it is a bit wavy.) You will note on the TPI table printed at the top of the gear and belt cover that only a few possible combinations are actually listed. The table at the bottom is for metric. There are to many combination to fit in the small space and the table includeds the 2x, 4x, 8x, lines so most are not even listed. The combinations not listed do seem to work, but I have not tried them all. I have not tried to do it yet, but I think one can figure out the gear ratios and then make a complete table of possible TPI without actually doing any measurements. (We will see.) The two feed rate tables for the cross slide are redundant between the English and metric.

Part 2 of my posting, "PM 1440GT Part 2 VFDDescript links wTable1 DNL LA10_1830.pdf", contains my design for the VFD conversion. Somewhat different from what others have done as I got rid of the big relays and transformers that come with the machine, used a few transistors instead and then I could fit everything in the original lathe stand.... no external boxes. The loose photos on the posting go with Part 2. You have to look in Part 1 to see the original machine photos as there are only 3 of these.

I assume you will being using 3phase power as you are considering the TL (only 3 phase motor available), but if not you can get the GT in single phase as well. I purchased the 3phase version knowing I was going to convert it. This has several advantages, especially the drive frequency variation. I sometimes wind electrical coils and it is nice to be able to set the frequency to a very low value and then gear the spindle down so that the spindle is turning very slowly. I also put a 10 pulse per revolution Hall sensor so I can get nice RPM readings, but more importantly I am now installing an electronic counter so that I can determine not only rotations, but fractions of a rotation in my windings. If you have not used a proximity stop for threading it is pretty handy. Others have posted about this, but it comes easily, and is accurate, with the VFD conversion.

Also, if you have not heard about it, there is a set up one can built called an "Electronic Lead Screw" that can generate any tpi you want with no gears or gear box. It uses a encoder at the spindle to determine the rotation and phase and then uses a stepper motor at the lead screw to determine the rotations of the lead screw via electronics. It appears to be a considerable built, but do able. Others on HM have repeated this work. See Clough42 on Youtube. There are several videos of his efforts. He even sells some of the parts needed.

But if you are making your living machining you may not have time for this effort! Maybe I will do it someday!

Hopes this helps. These are not easy decisions!

Dave