- Joined

- Dec 30, 2024

- Messages

- 12

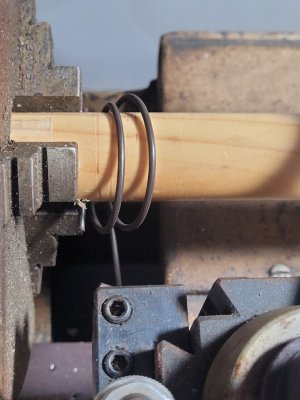

Well, I am actually about the same age as my Atlas 10" lathe. I was probably in my early teens when my Dad got this lathe being used to wind wire ?? He added a 3 and 4 jaw chuck and a modern tool post (still have the original). As he got older, it sat mostly unused in the basement until after his passing, I moved it from CT to NC and sat in my non-conditioned shop for several years. Now my brother is rebuilding the swinging cradle that probably each of us swung in , now for his new granddaughter. It has a 36" long wound spring to power the rocking but broken into many pieces. And he wants to use the lathe to wind some spring wire. We chucked a wood dowel and turned the chuck by hand to proved it was possible. see pics

I want to thank Markba633csi for his invaluable help in wiring up the original motor to a new drum switch - got it working tonight. I adjusted the belts to the slowest rpm. And I got the back gears working reasonably quietly as well. Since we are using 1/8" wire, I set the QC gearbox to 8 tpi.

So now a couple of questions:

1. In our sample, we fed the wire behind a cutting tool in the toolpost and that worked well. Now we plan to check a 36" piece of 1 1/4" pipe and wind the spring around it and use the threading gearing to move the feed down as we rotate the pipe. Any risk to breaking something? Or suggest a better way?

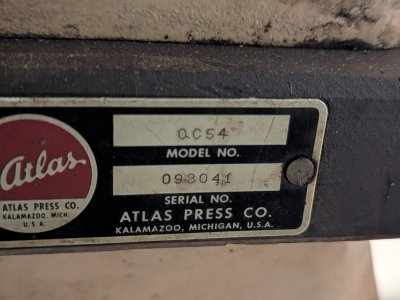

2. This is a QC54, SN 093941, looking at the database file I found in this forum, it seems the lathe was built roughly 1953?

3. I don't ever remember my Dad saying anything about lubrication the lathe and I will order some Mobil Vactra 2 and Velocite 10 to use but can I use some light machine oil or pneumatic tool oil for now? I read some discussion about felts in the oiler cups. What is the purpose of the felt? And best way to clean the long lead screw?

4. Unfortunately, between the time in the basement and now the humid NC summers, the ways have a little rust on them. What is the best way to clean this up?

5. Lastly, the lathe came with both a steady rest and a follower rest and a whole bin of threading gears. Doesn't the QC gearbox make the threading gears superfluous?

I have read quite a few threads aboout the Atlas lathes and very happy to have found this group and appreciate all the help. Ed

I want to thank Markba633csi for his invaluable help in wiring up the original motor to a new drum switch - got it working tonight. I adjusted the belts to the slowest rpm. And I got the back gears working reasonably quietly as well. Since we are using 1/8" wire, I set the QC gearbox to 8 tpi.

So now a couple of questions:

1. In our sample, we fed the wire behind a cutting tool in the toolpost and that worked well. Now we plan to check a 36" piece of 1 1/4" pipe and wind the spring around it and use the threading gearing to move the feed down as we rotate the pipe. Any risk to breaking something? Or suggest a better way?

2. This is a QC54, SN 093941, looking at the database file I found in this forum, it seems the lathe was built roughly 1953?

3. I don't ever remember my Dad saying anything about lubrication the lathe and I will order some Mobil Vactra 2 and Velocite 10 to use but can I use some light machine oil or pneumatic tool oil for now? I read some discussion about felts in the oiler cups. What is the purpose of the felt? And best way to clean the long lead screw?

4. Unfortunately, between the time in the basement and now the humid NC summers, the ways have a little rust on them. What is the best way to clean this up?

5. Lastly, the lathe came with both a steady rest and a follower rest and a whole bin of threading gears. Doesn't the QC gearbox make the threading gears superfluous?

I have read quite a few threads aboout the Atlas lathes and very happy to have found this group and appreciate all the help. Ed