I edited your post for brevity; apologies for that.

Not a problem, makes it easier to know which part you are responding to.

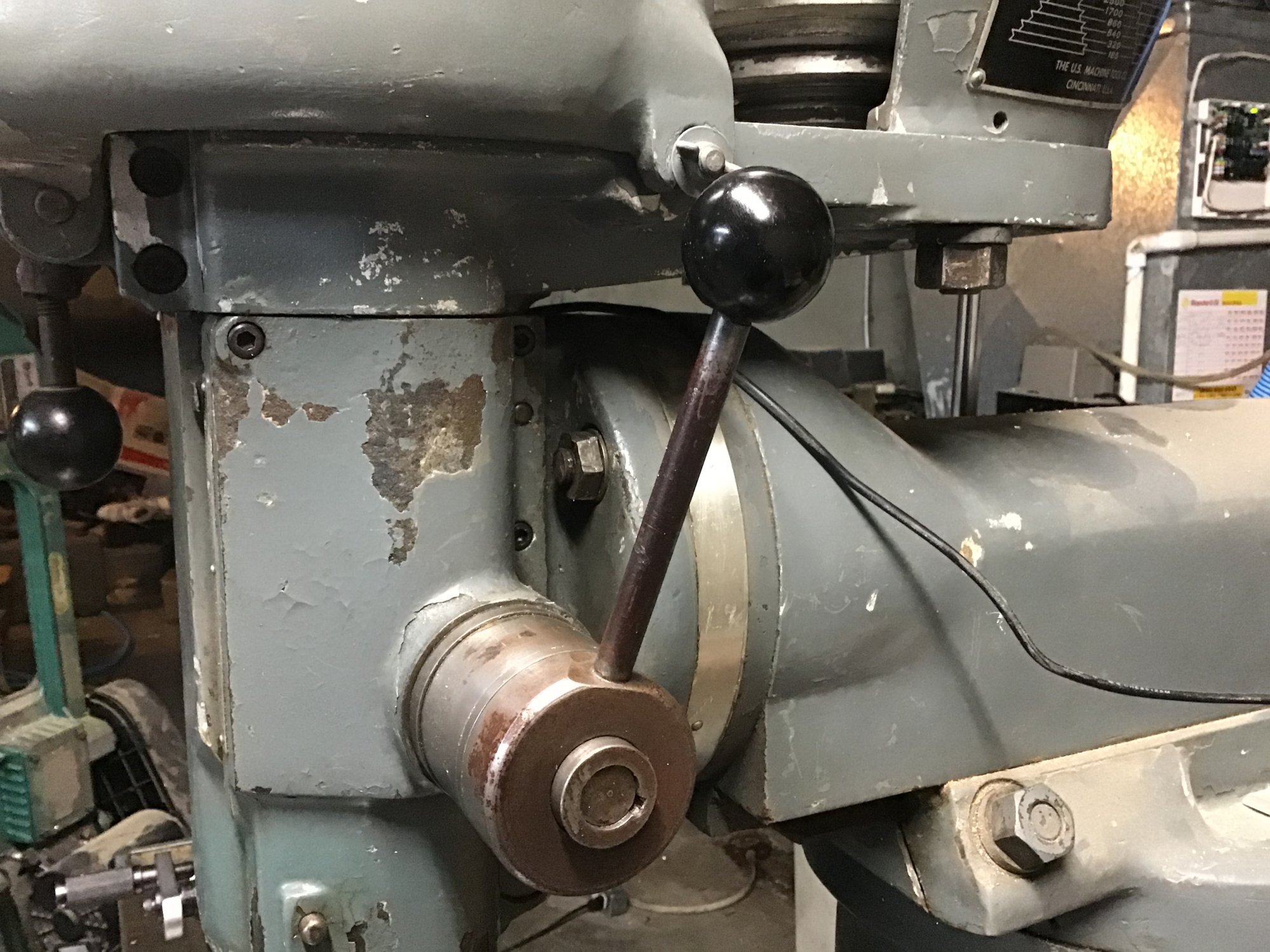

Here are a few pictures to help you decide how much you might want to disassemble it. This is the quill/ram assembly.

The quill housing is mounted to the front of the ram by 4 bolts, these are the bolts I mentioned if you loosen them, the quill housing and motor can quickly rotate on you, there is no gear mechanism like on a Bridgeport to adjust the angle, it is either loose, or tight. When loosening the bolts, leave one tight and then slowly loosen while holding on to the motor and then rotate down. It’s heavy, so be prepared. You can remove the housing by taking those 4 bolts out and pulling it towards you if you are facing the mill. Do not hoist by the motor mounting plate, that is only held on by a pinch bolt that clamps to the housing and there is a risk it could come off if not secure enough. Wrap the sling around the housing instead.

You can remove the entire quill/ram assembly as one piece, but it will rotate on you, so make sure you support it to keep from rotating like in the previous paragraph if you choose to do that. If you remove the quill housing first, place a sling under the ram and lift up after removing the nuts shown below.

These bolts are 5/8” diameter, so if you are using eye bolts to lift the base, that is the maximum size to have on hand.

I removed the table to get it into my basement, you shouldn’t need to do that to move it, but if you need to, remove components from this end. You will need Allen wrenches as well as a pin wrench to remove the lock nut for the bearings. I use an adjustable type with a 3/16” pin. You then use the other end hand wheel to unscrew the leadscrew and take the table off. I used my engine hoist with eye bolts in the T slots of the table to support the weight.

I attached a pdf manual for the mill that shows the parts breakdown to give you a better visual of the parts being removed.